- Angular Contact Ball Bearings

- Bearings For Auto Motive

- Cam Clutch, Sprag Freewheels & Roller Type OWC Series

- Cylindrical Roller Bearings

- Deep Groove Ball Bearings

- Linear Motion Bearings

- Needle Roller Bearings

- Pillow Block And Insert Bearings

- Powder Metal Parts

- Roller Chains

- Self-Aligning Ball Bearings

- Spherical Plain Bearings

- Spherical Roller Bearings

- Tapered Roller Bearings

- Thrust Ball Bearings

01

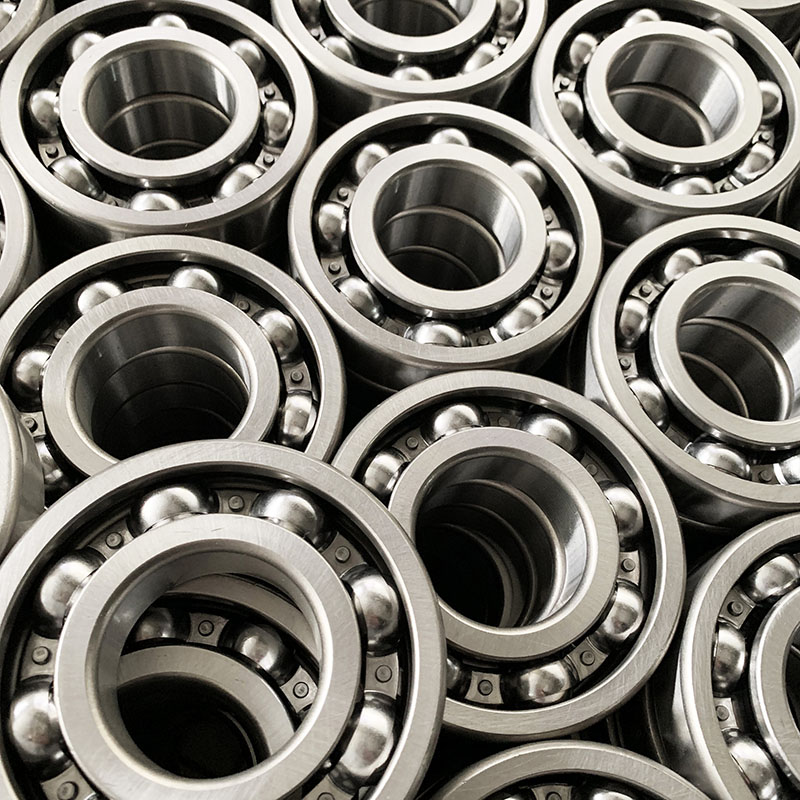

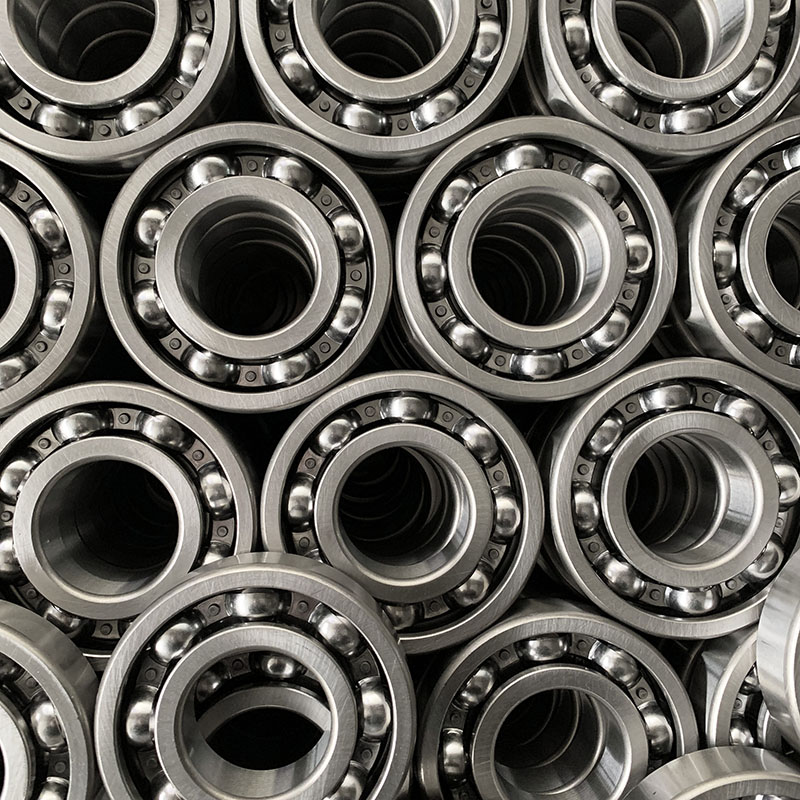

Deep Groove Ball Bearings in China

Description

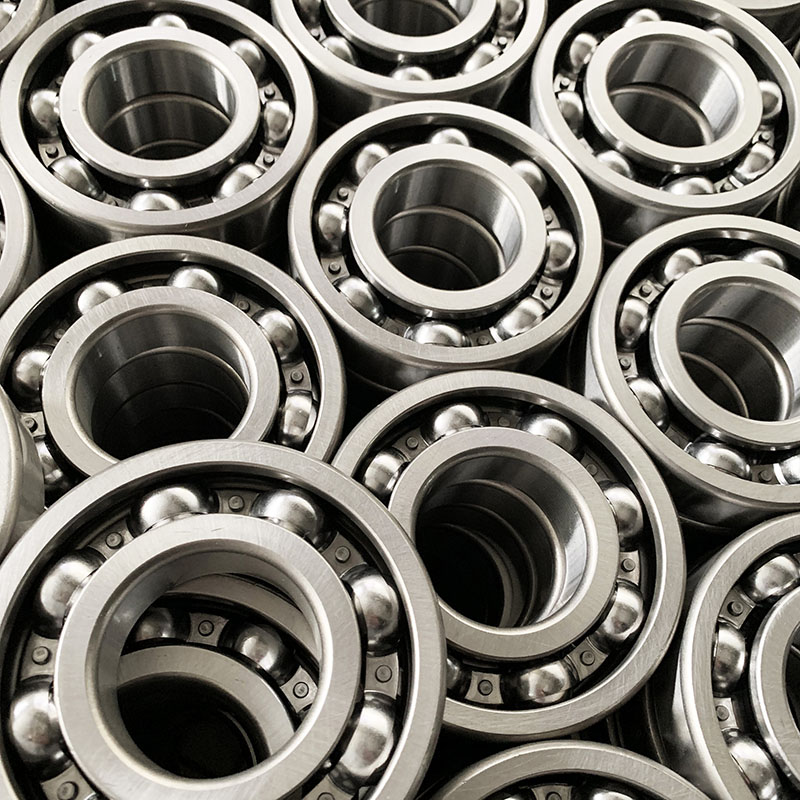

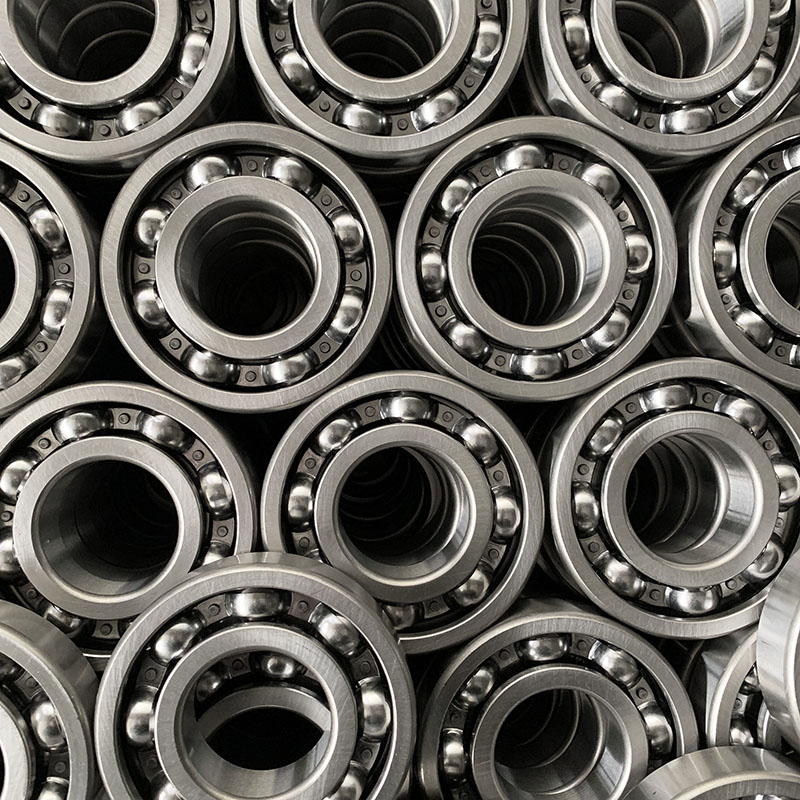

Deep groove ball bearing is a common rolling bearing, suitable for bearings that bear large radial loads and partial axial loads. Deep groove ball bearings have low friction coefficient and high rotational speed performance, so they are widely used in many equipment and mechanical devices. The basic type of deep groove ball bearing consists of an outer ring, an inner ring, a set of steel balls and a set of cages. There are two types of deep groove ball bearing, single row and double row, deep groove ball structure is also divided into sealed and open two structures, open refers to the bearing does not have a sealed structure, sealed deep groove ball is divided into dust seal and oil seal. The dust seal cover material is steel plate stamping, which only plays a simple role in preventing dust from entering the bearing raceway. The oil-proof type is a contact oil seal, which can effectively prevent the leakage of grease in the bearing.Single row deep groove ball bearing type code is 6, double row deep groove ball bearing code is 4. Its structure is simple, easy to use, is the most common production, the most widely used class of bearings.

The design structure of deep groove ball bearings is composed of annular raceways with inner and outer cylindrical grooves and a set of rolling elements (usually steel balls). This type of bearing is popular for its simplicity, economy, ease of installation and maintenance. Deep groove ball bearings can be used in a variety of applications such as: power tools, automotive transmissions, agricultural machinery, fans, conveying equipment, etc.

For deep groove ball bearings, attention should be paid to ensuring the bearing's axial clearance and proper lubrication during installation to ensure its normal operation and extend its service life.

Features of deep groove ball bearings include

● Compact structure

Deep groove ball bearings adopt a simple structure, consisting of inner and outer rings and spheres.The structure is compact and easy to install and disassemble.

● Strong load-bearing capacity

It can bear radial load and axial load, and is suitable for force loading in a variety of different directions.

● Flexible use

Deep groove ball bearings are suitable for a variety of industrial applications, such as machinery and equipment, automobiles, motorcycles, etc.

● High speed

It has good speed performance and is suitable for high-speed operation.

● Oriented to high precision

It can provide high-precision rotation performance and is suitable for precision machinery and equipment.

● Less maintenance

Typically, deep groove ball bearings are easy to maintain and have a long service life.

Deep groove ball bearings have been widely used in the industrial field because of the above characteristics.

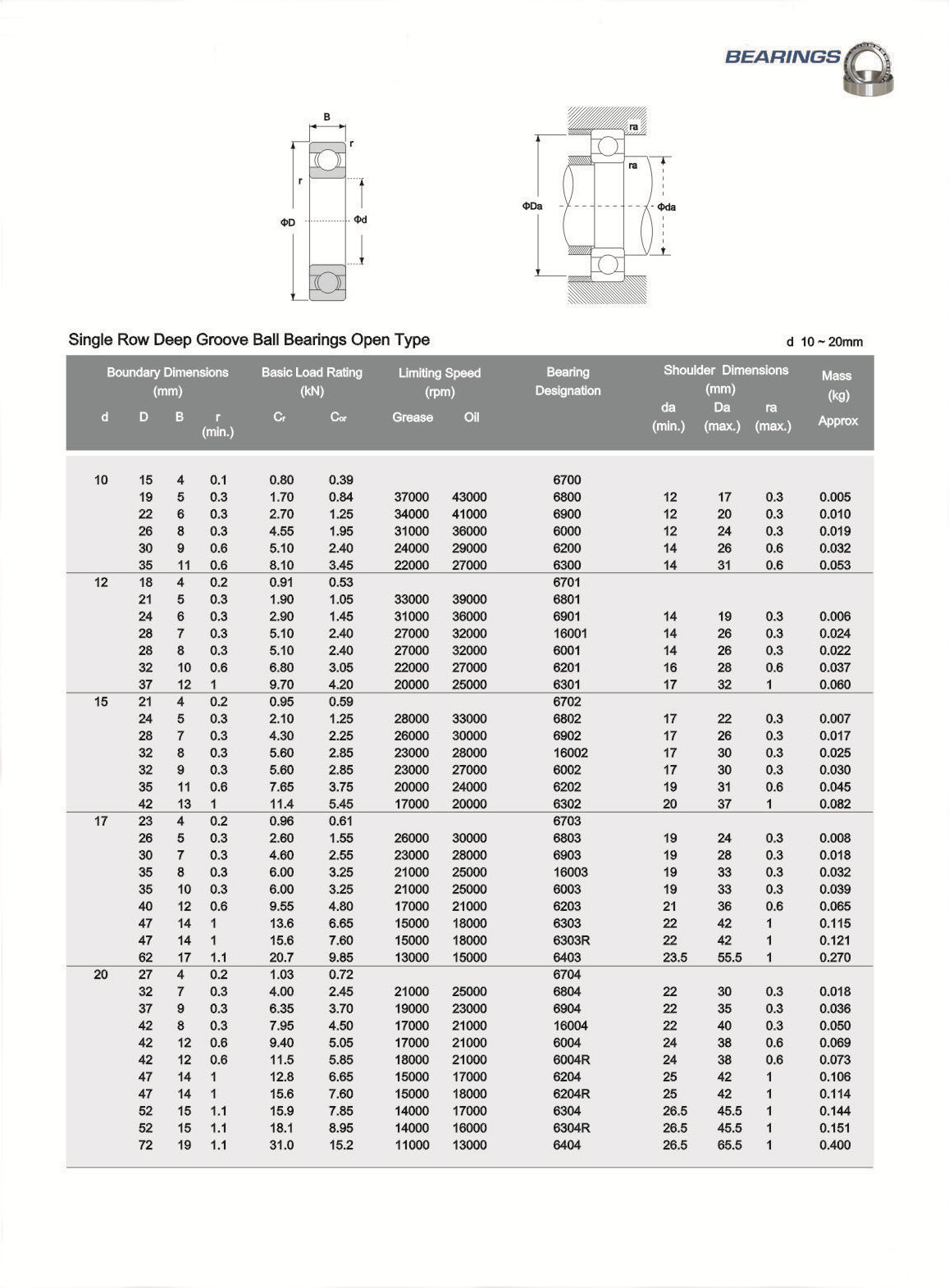

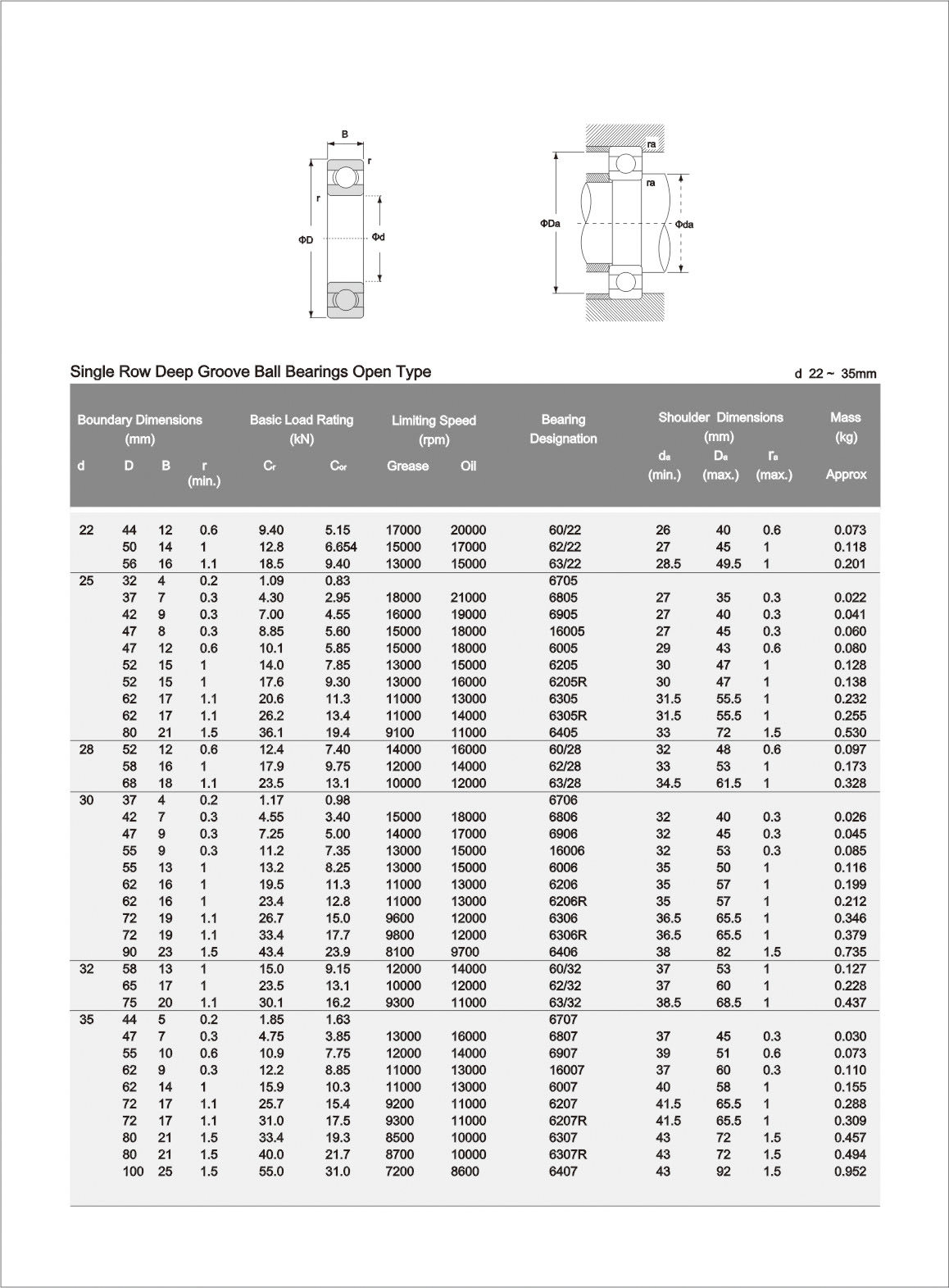

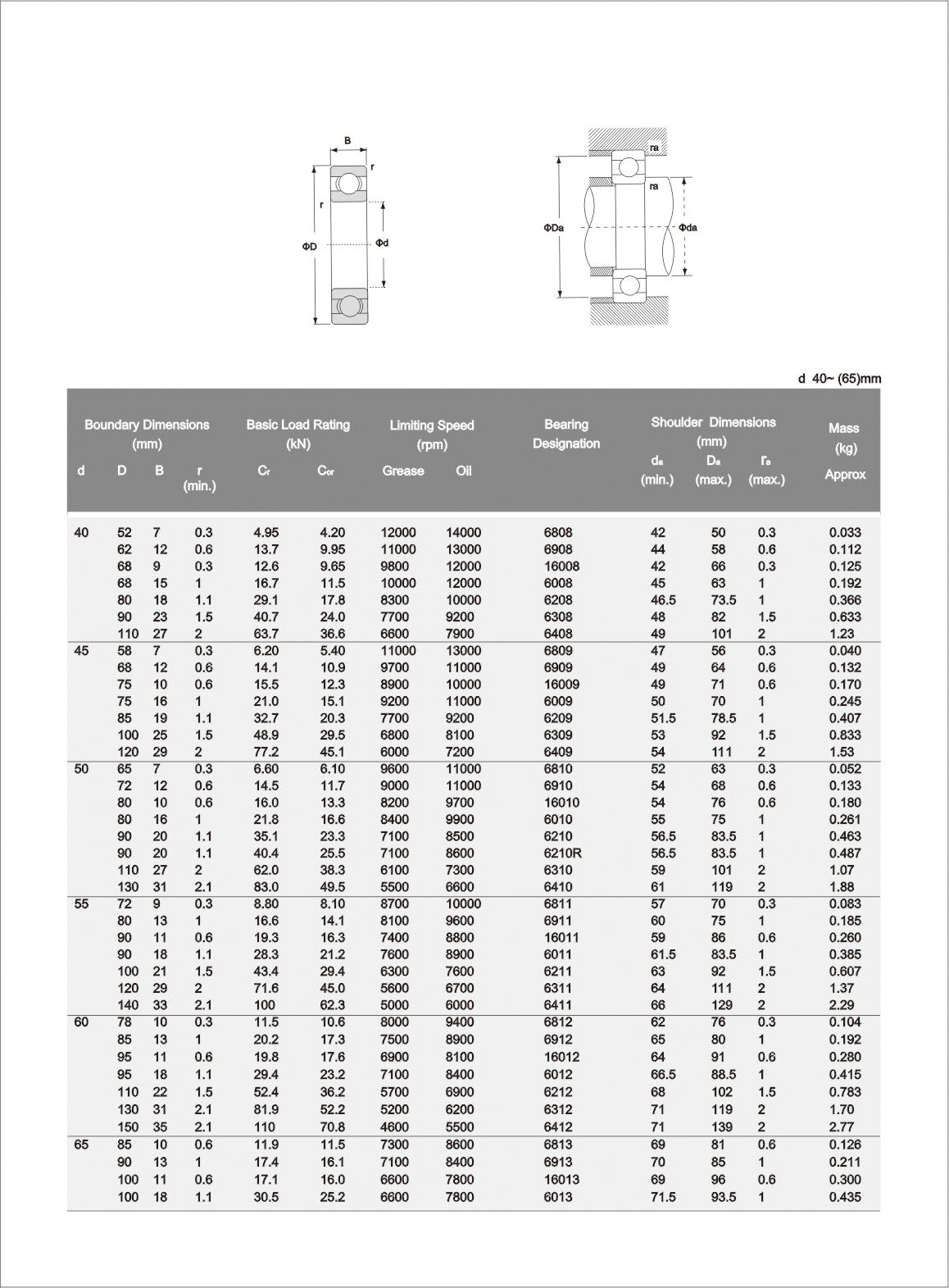

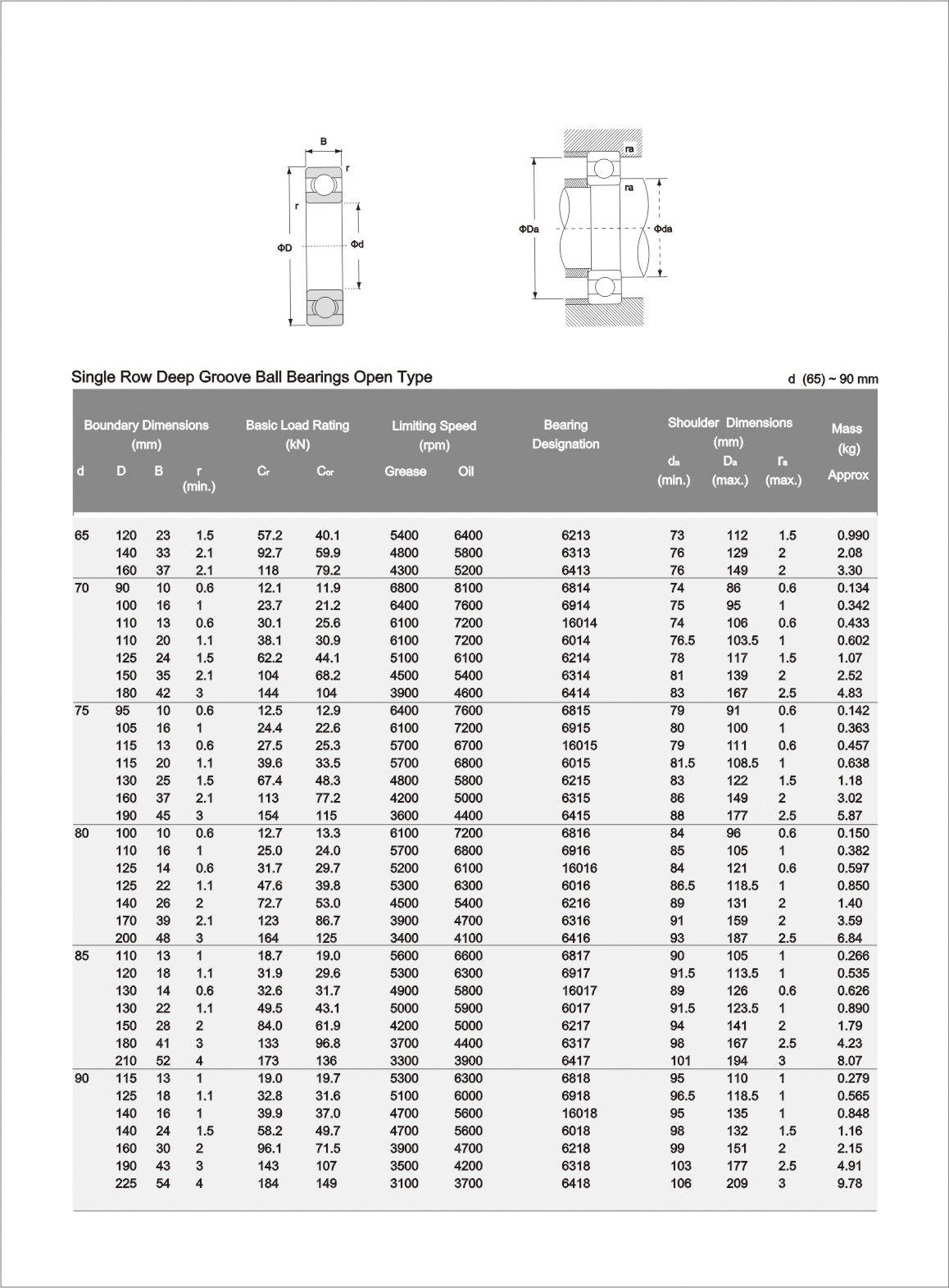

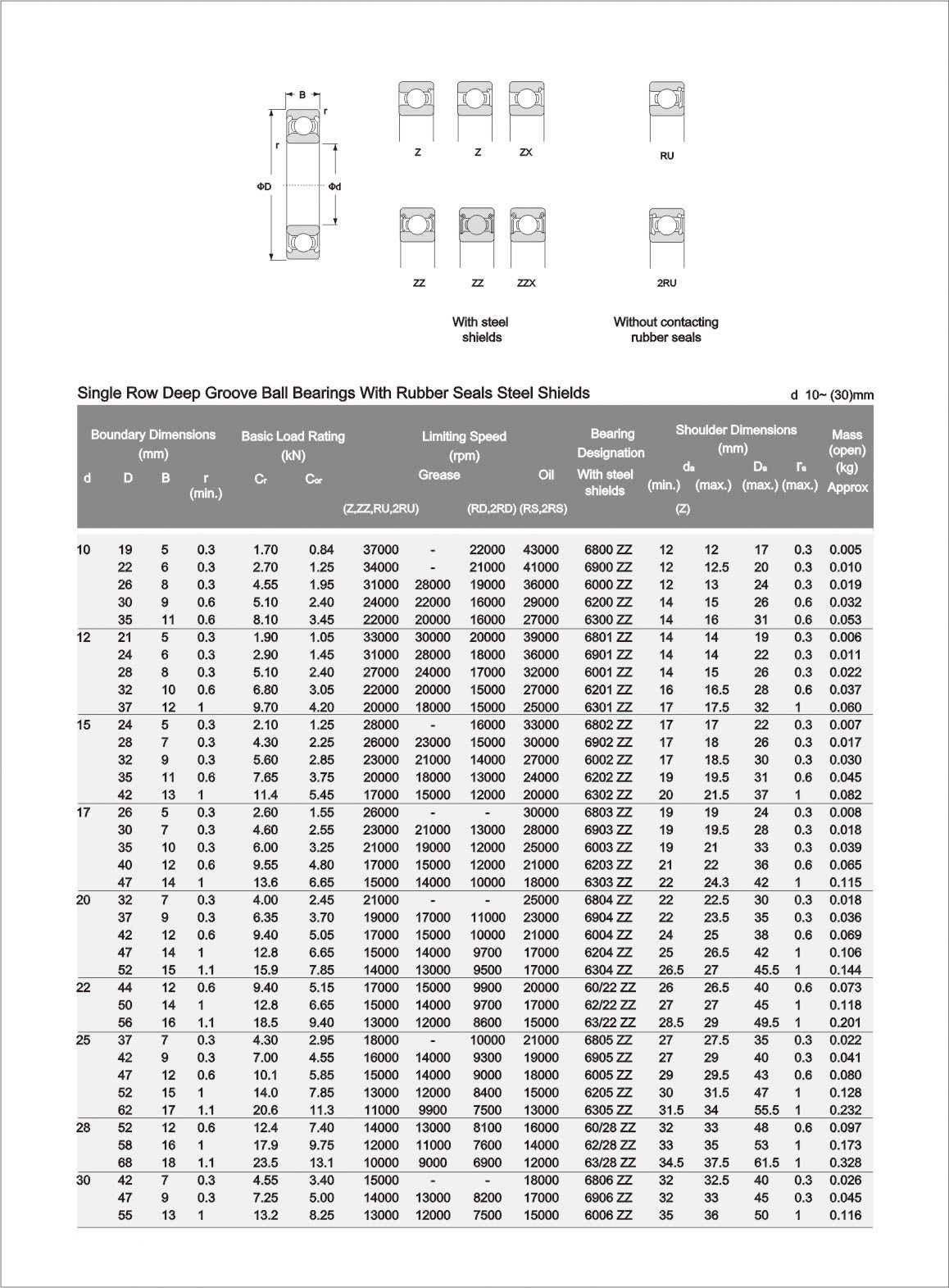

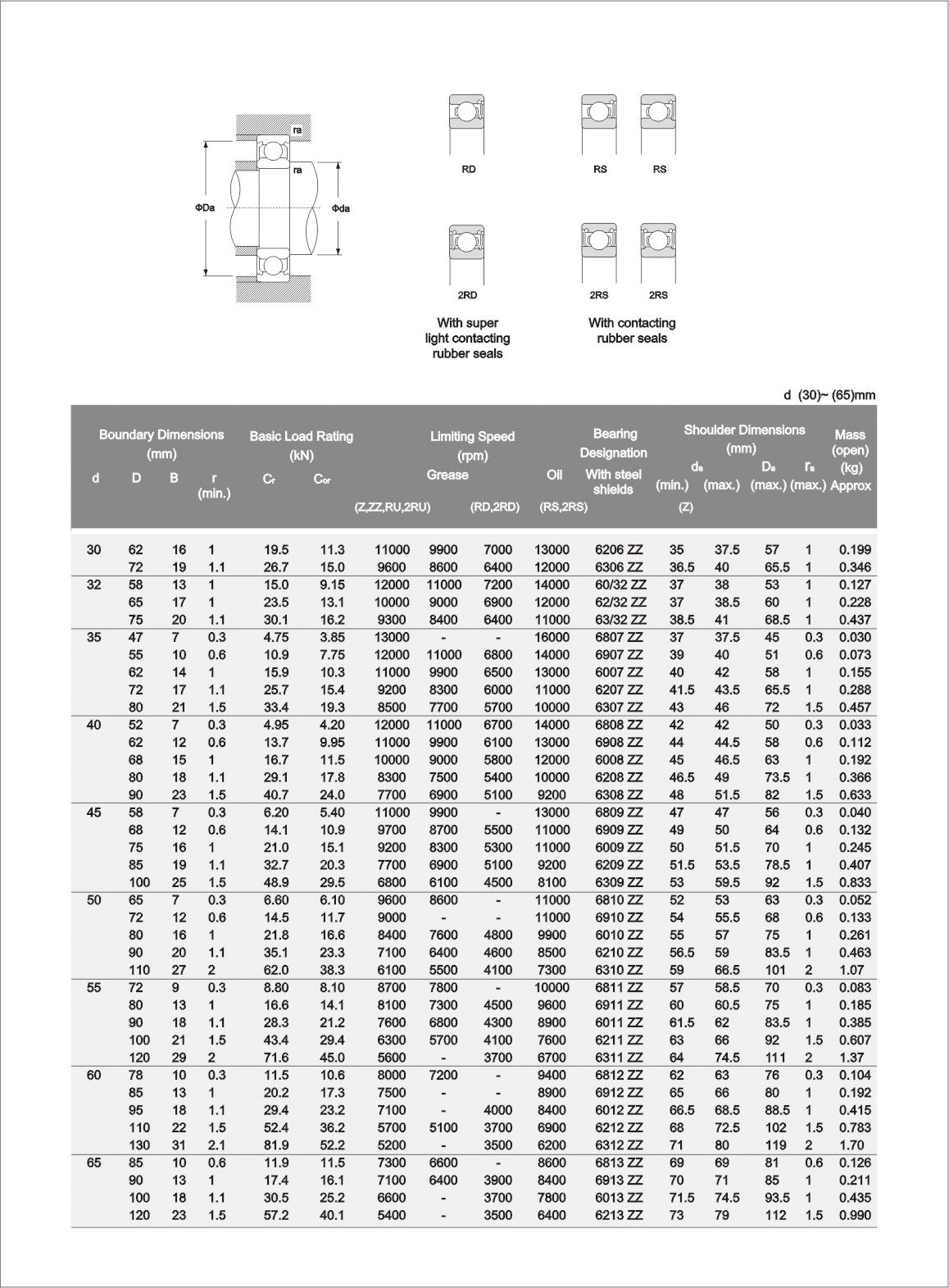

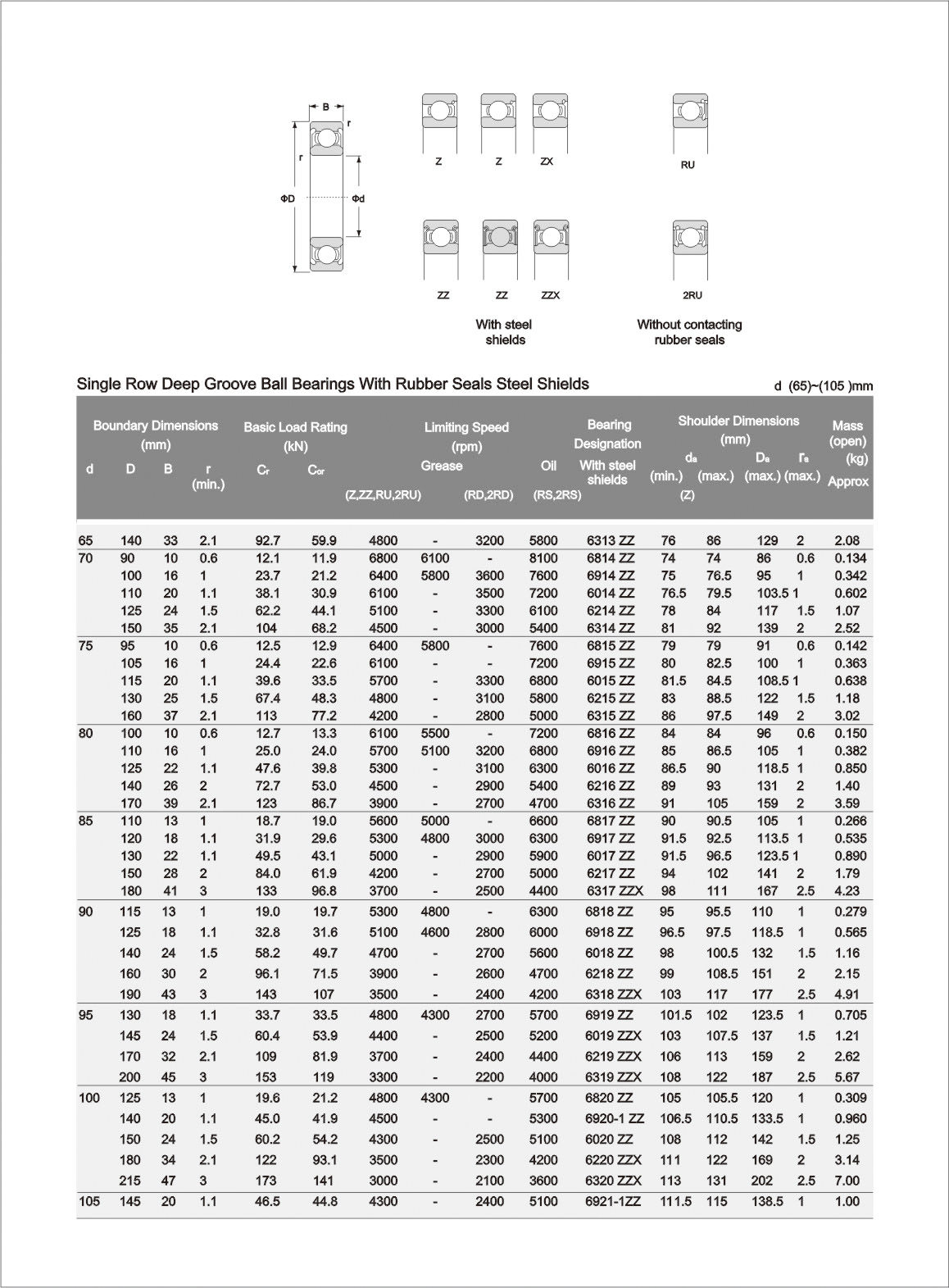

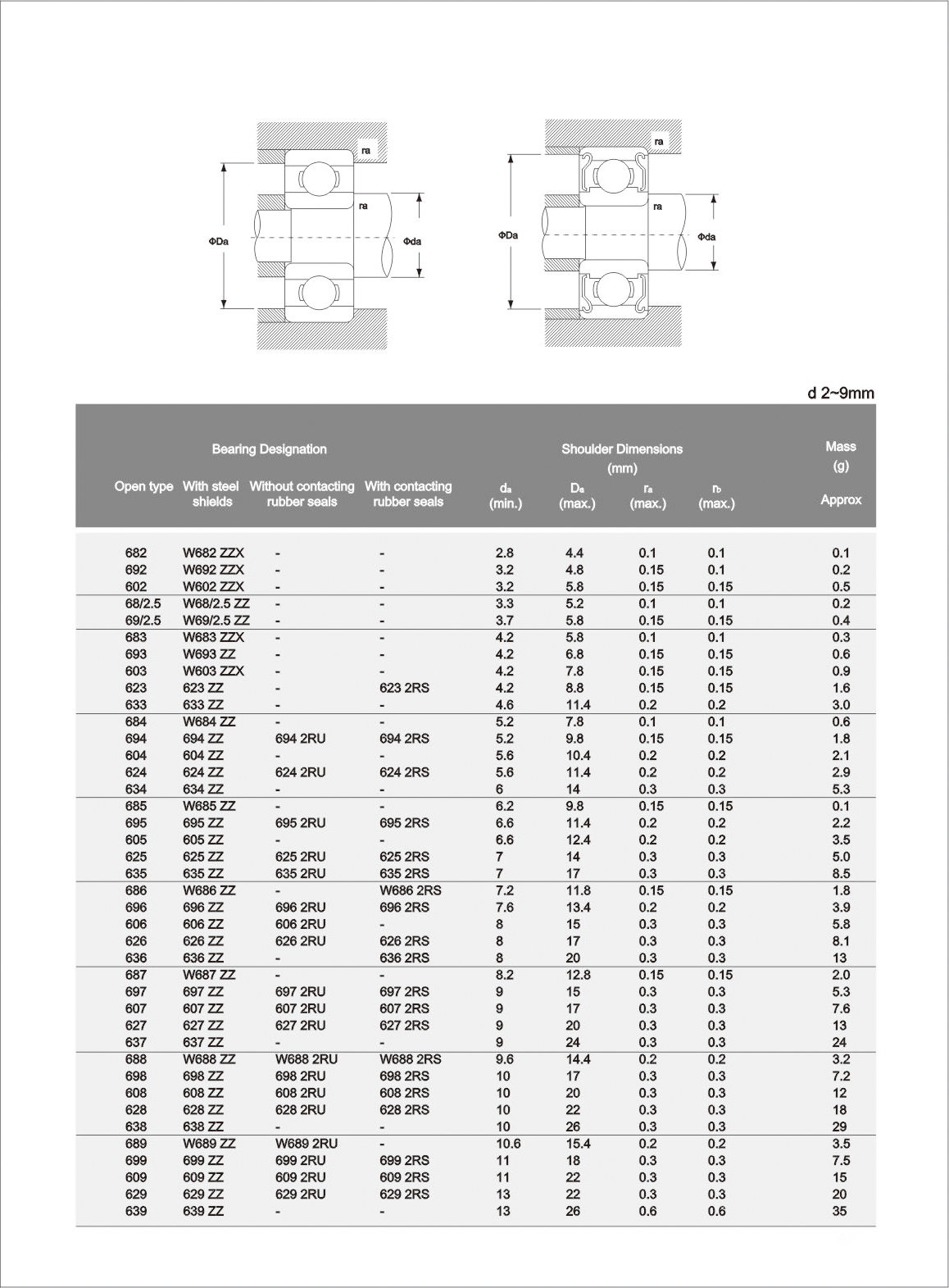

Product Drawing

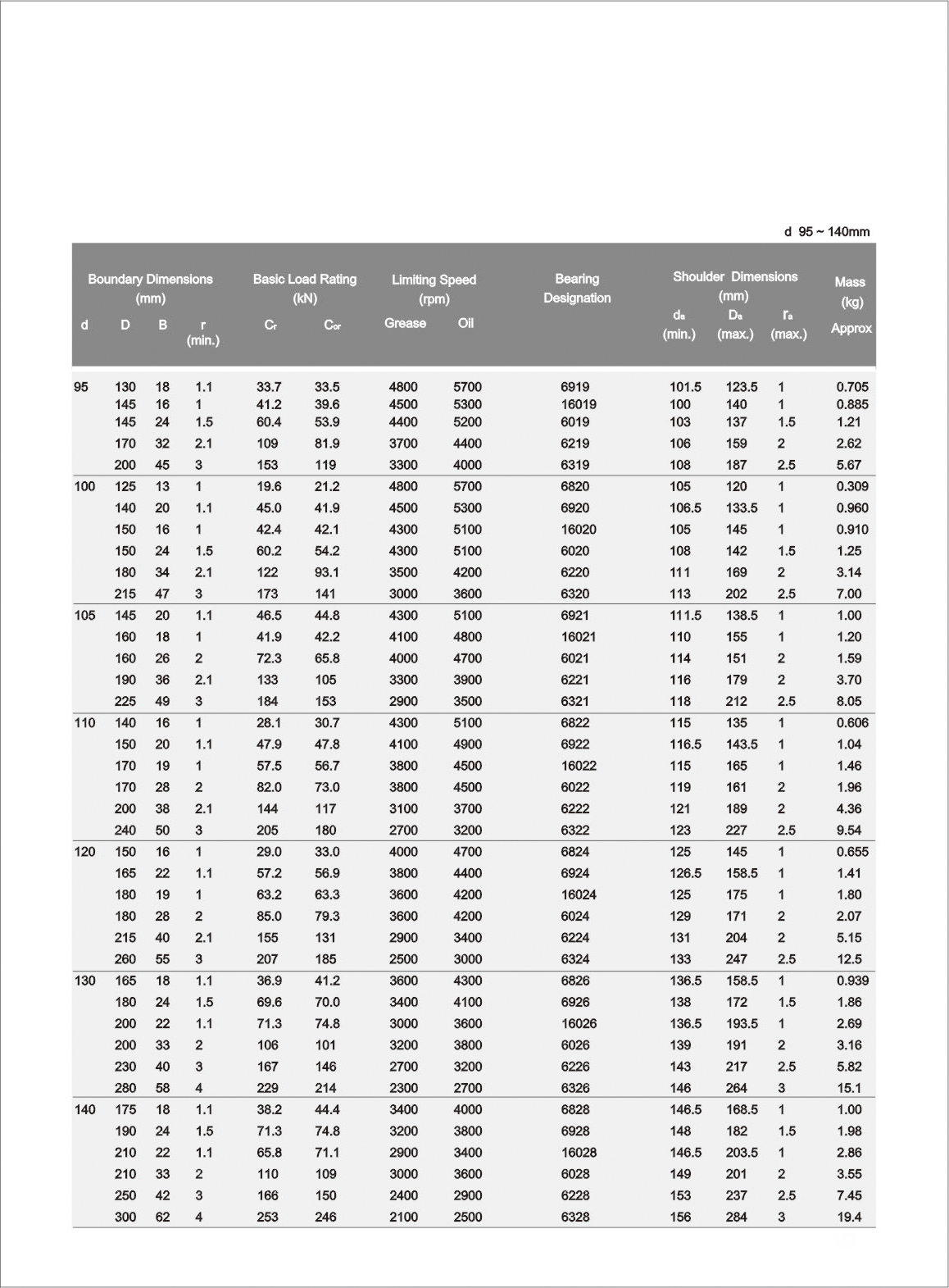

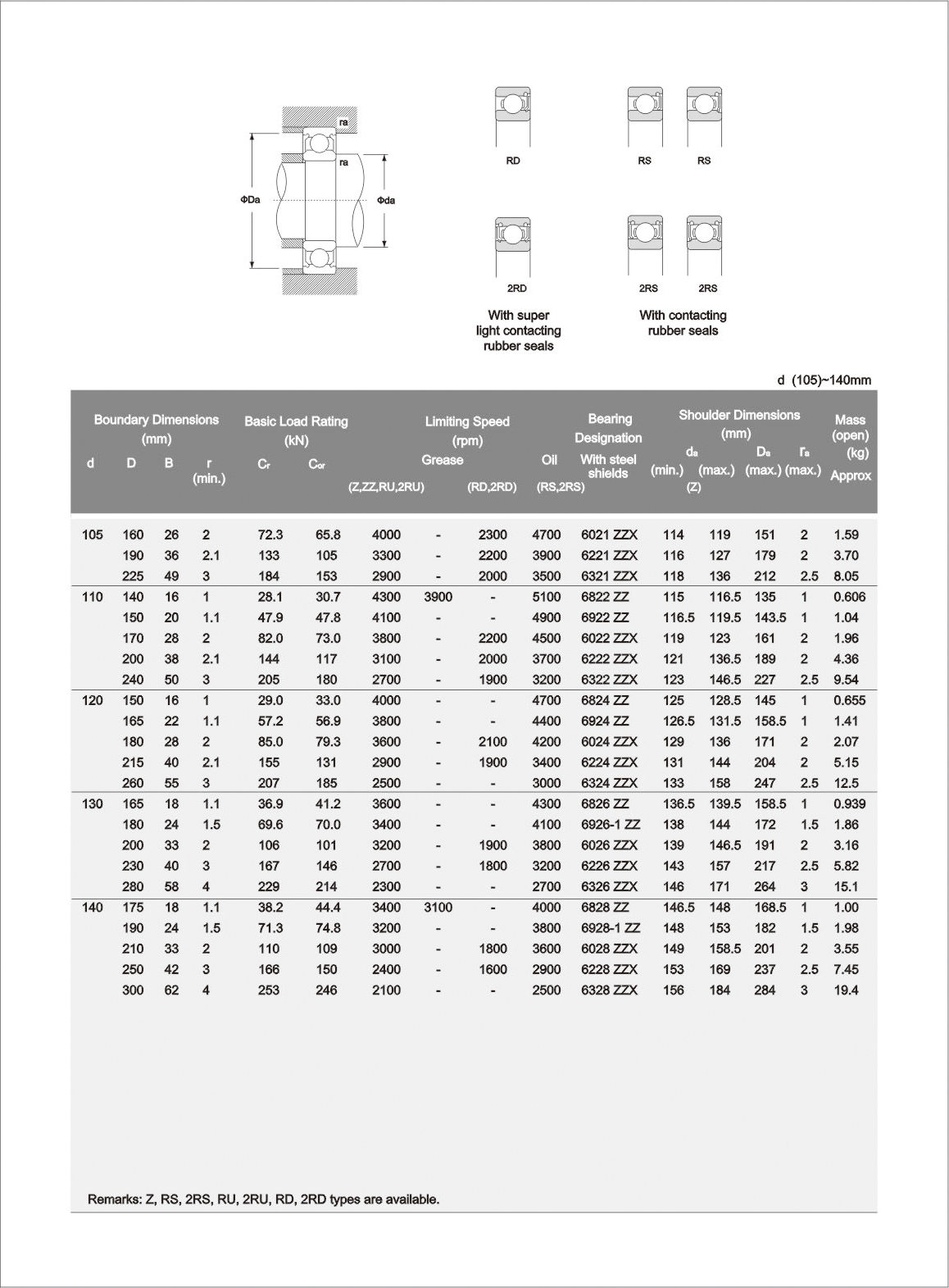

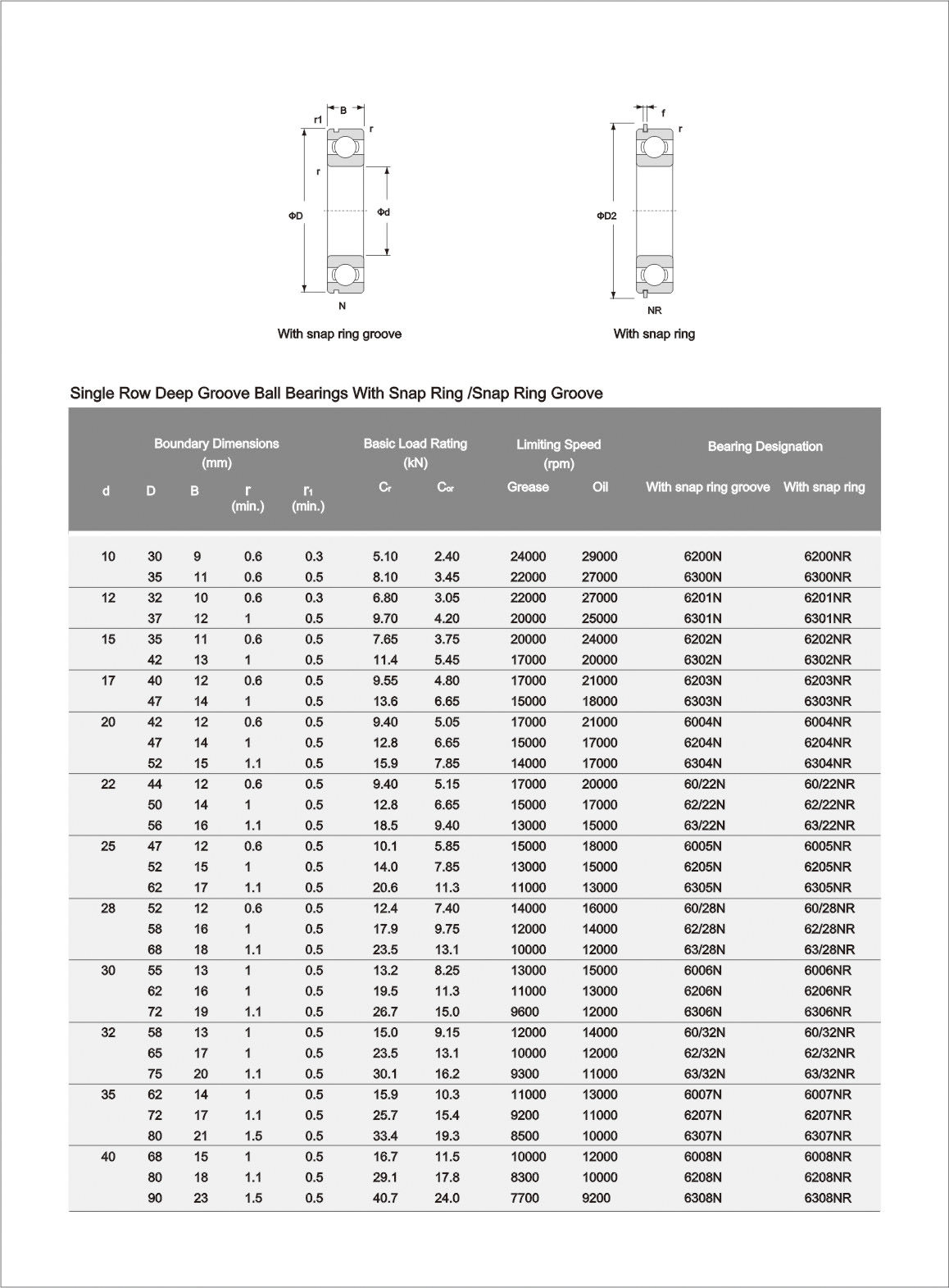

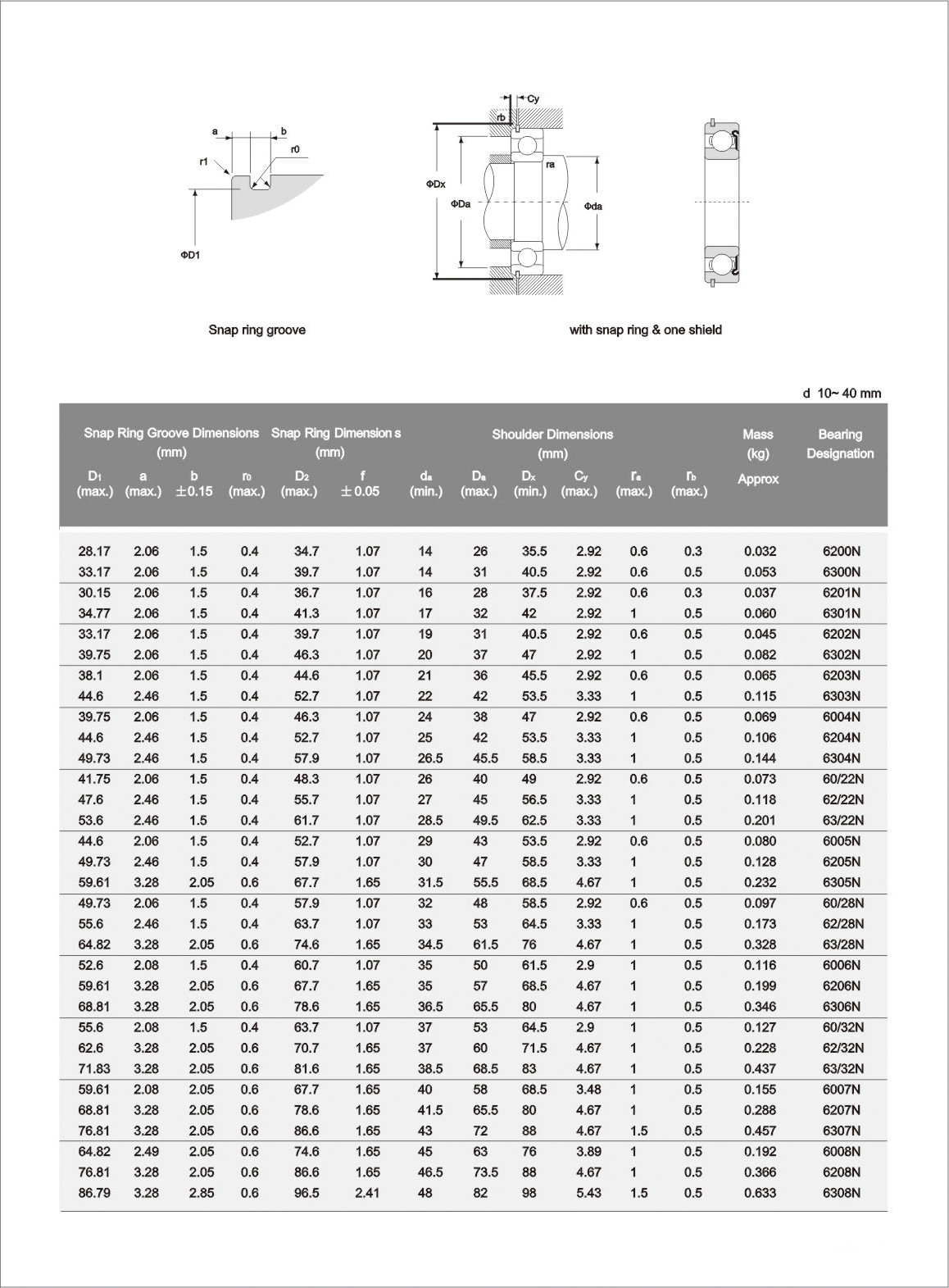

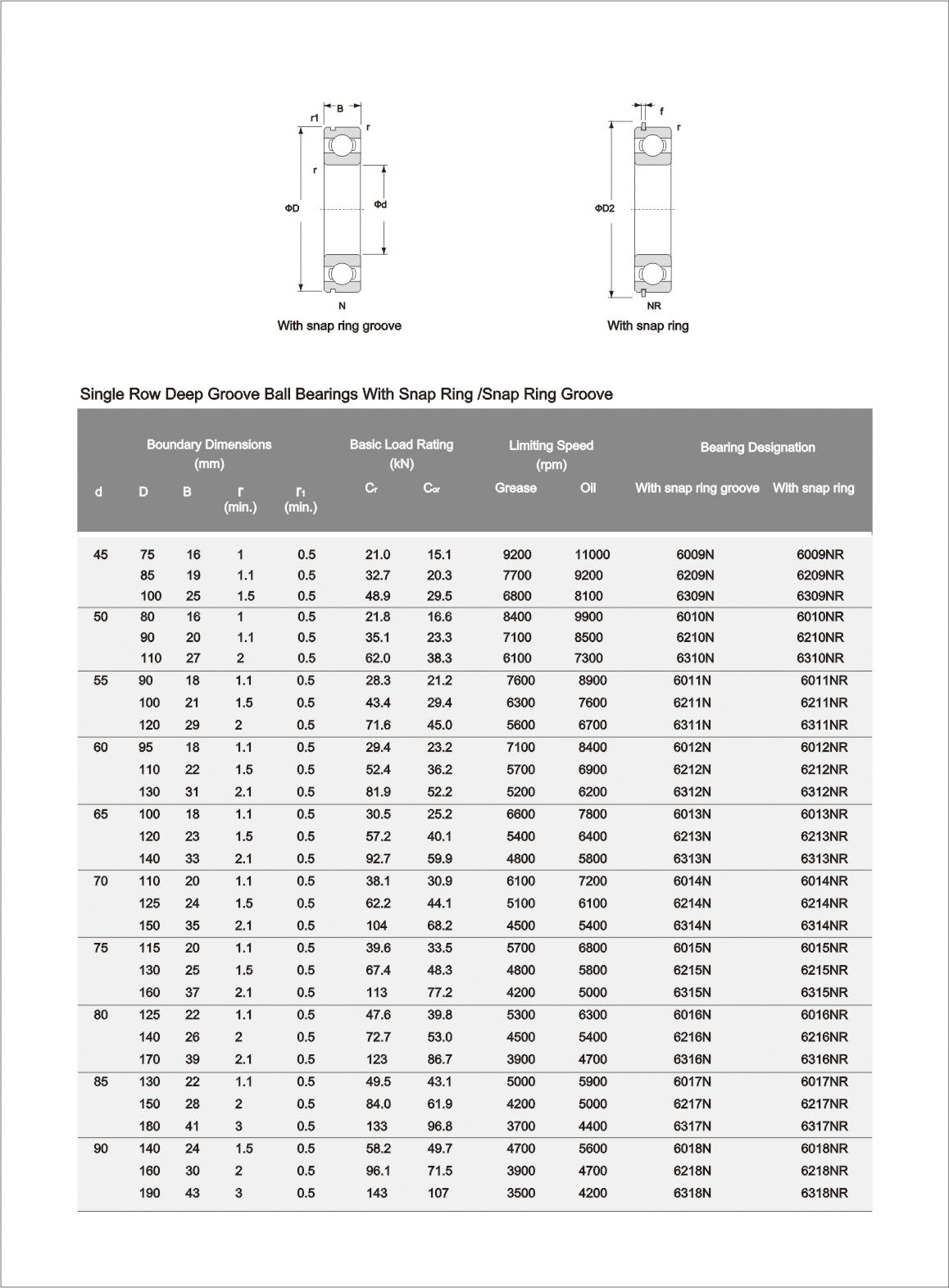

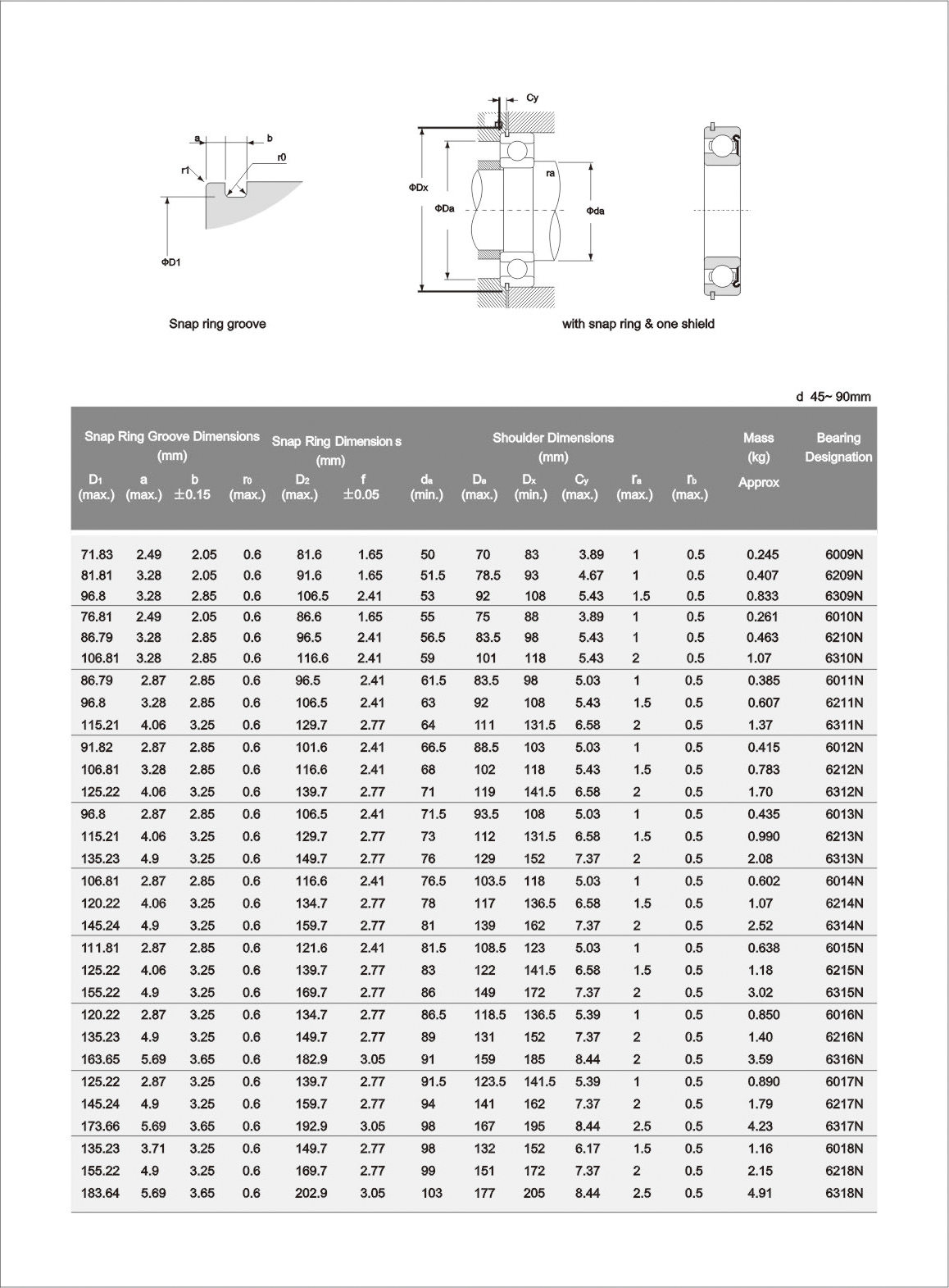

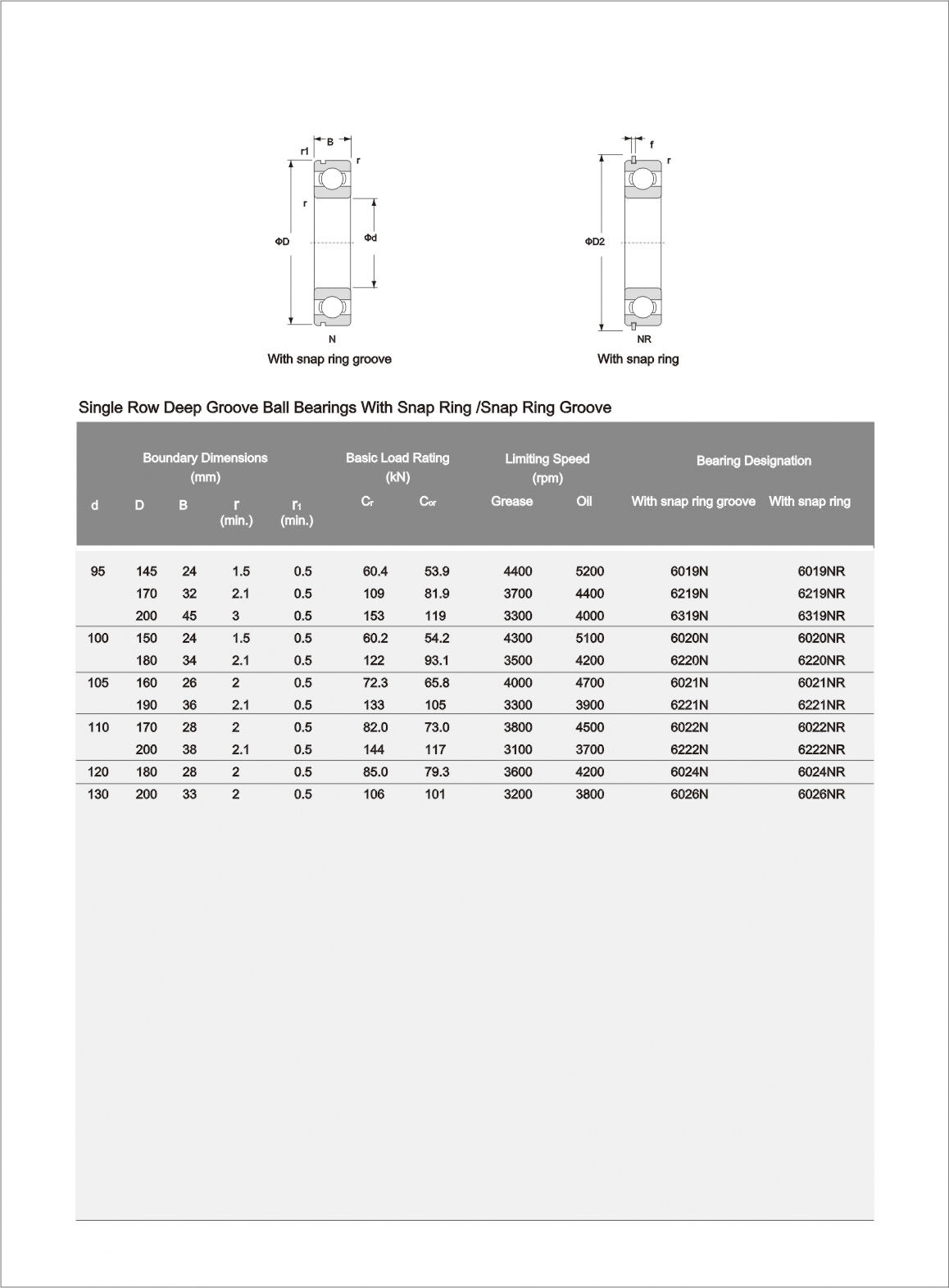

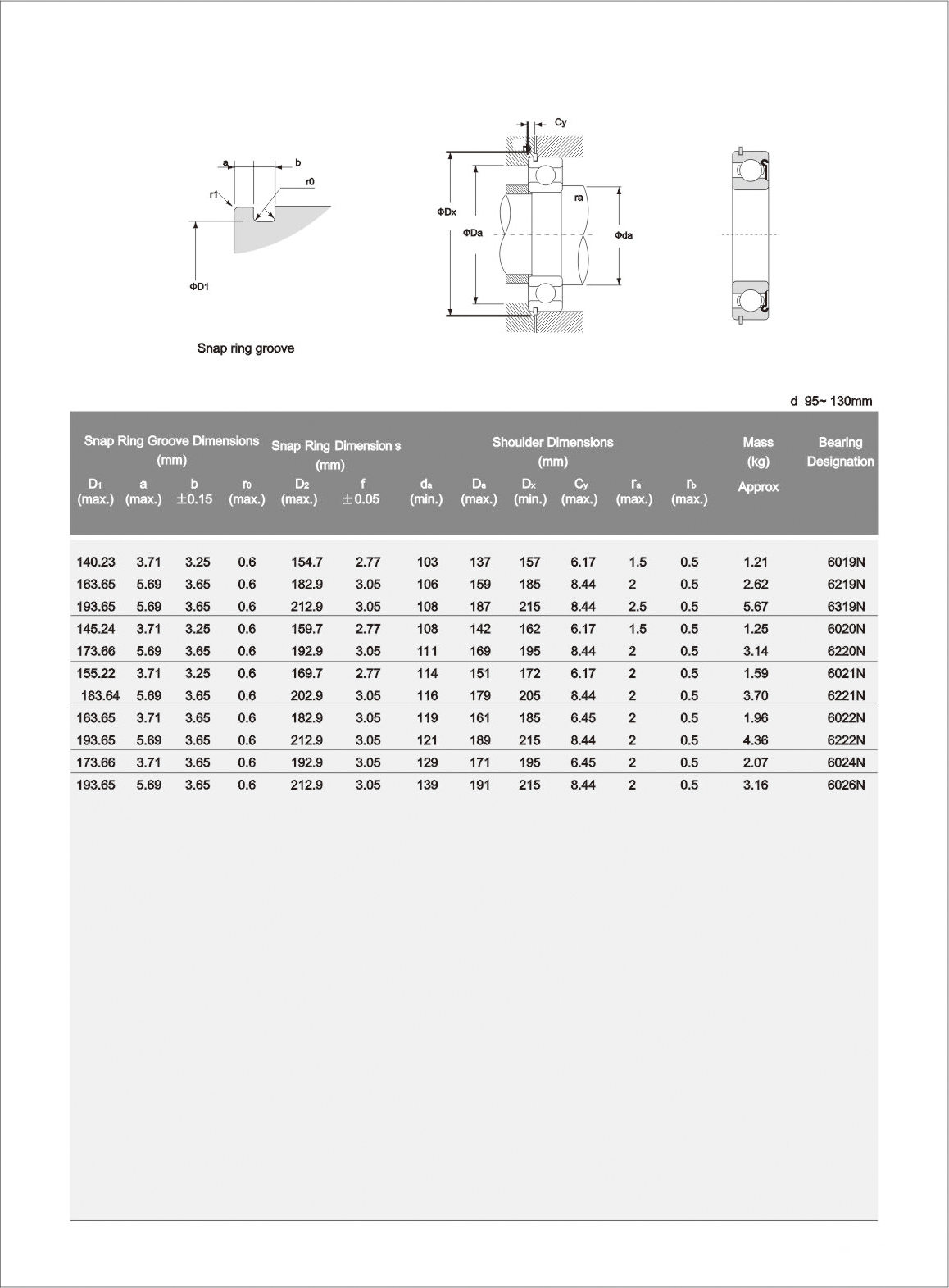

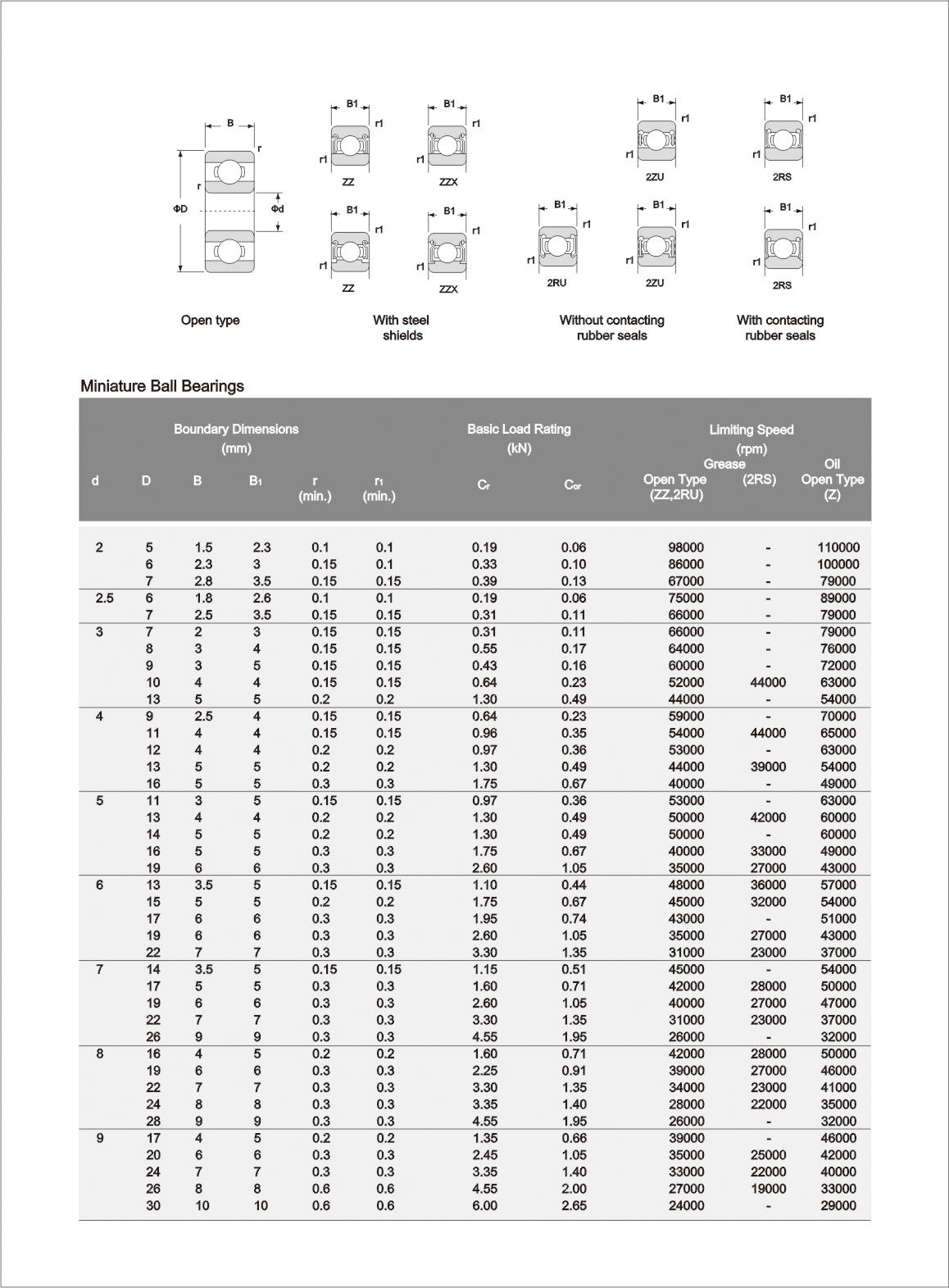

Catalog