- Angular Contact Ball Bearings

- Bearings For Auto Motive

- Cam Clutch, Sprag Freewheels & Roller Type OWC Series

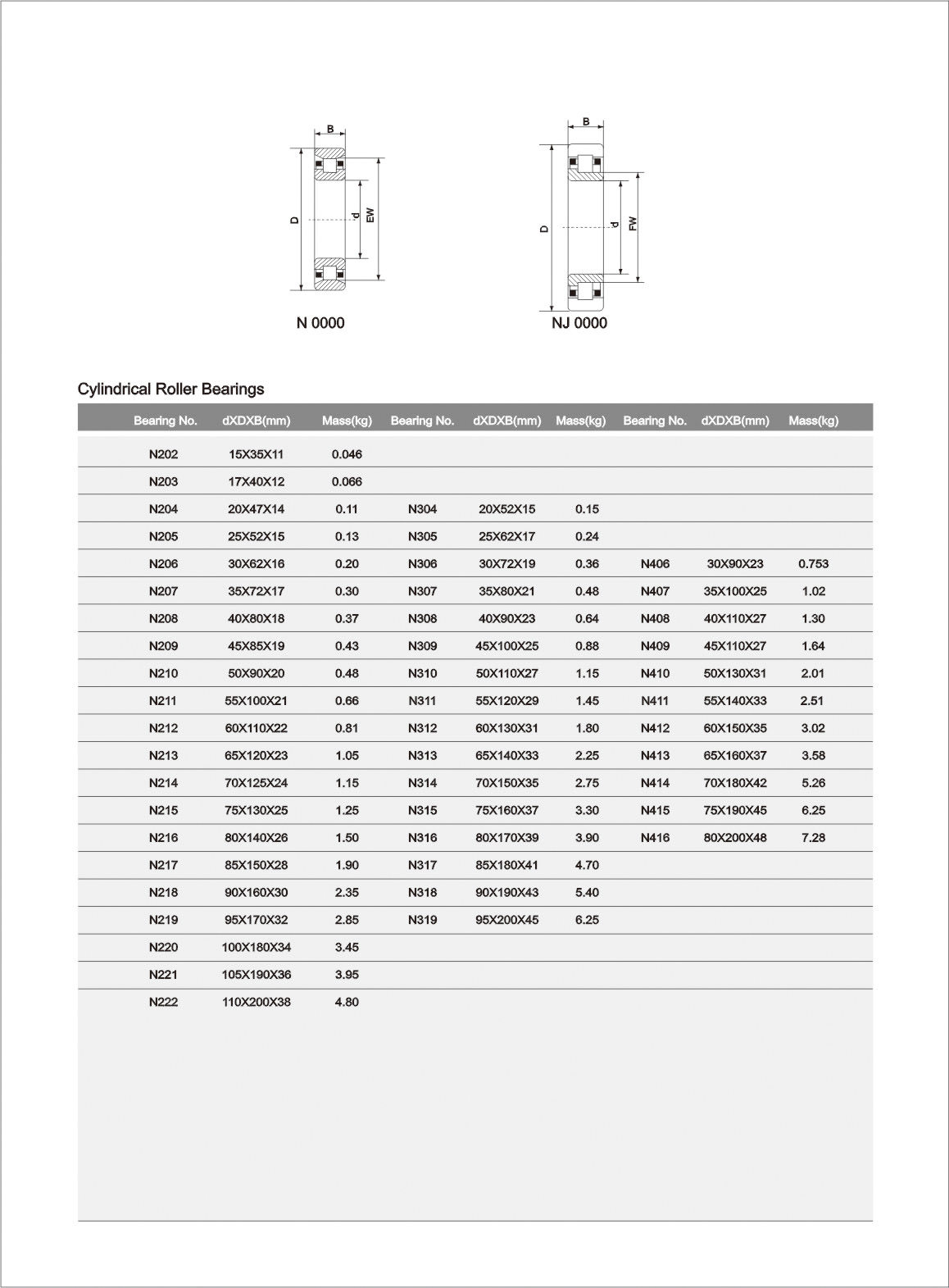

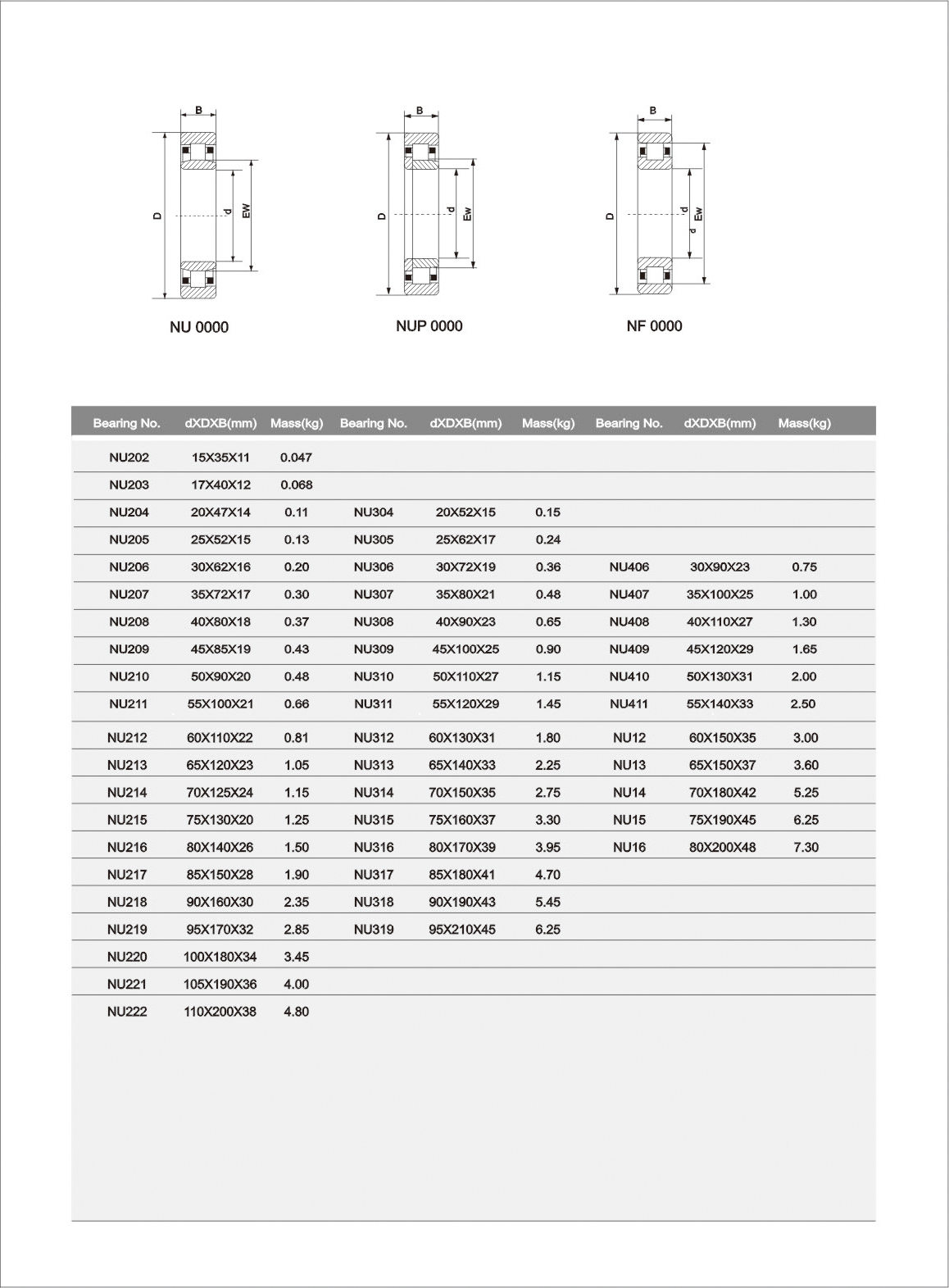

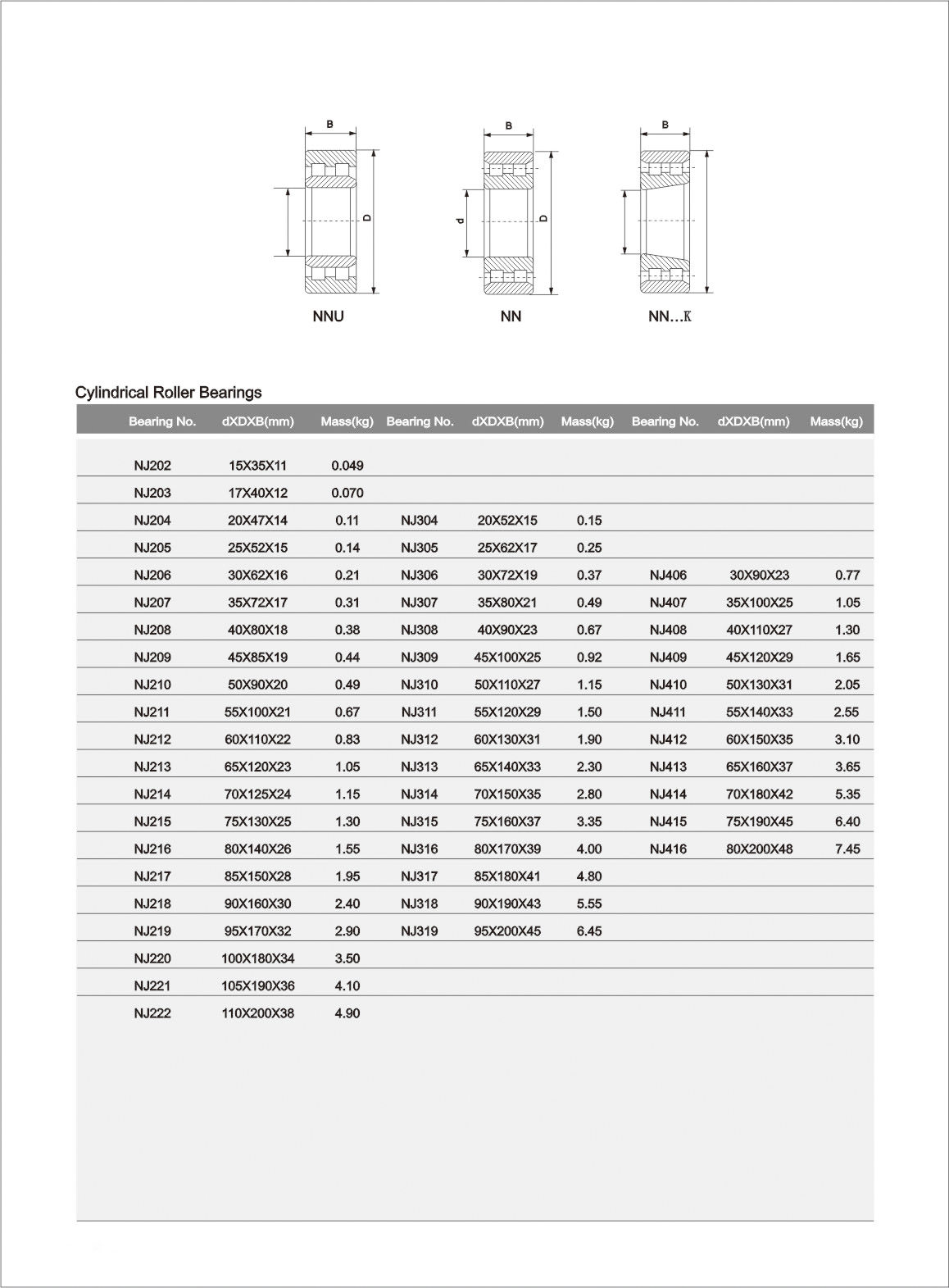

- Cylindrical Roller Bearings

- Deep Groove Ball Bearings

- Linear Motion Bearings

- Needle Roller Bearings

- Pillow Block And Insert Bearings

- Powder Metal Parts

- Roller Chains

- Self-Aligning Ball Bearings

- Spherical Plain Bearings

- Spherical Roller Bearings

- Tapered Roller Bearings

- Thrust Ball Bearings

01

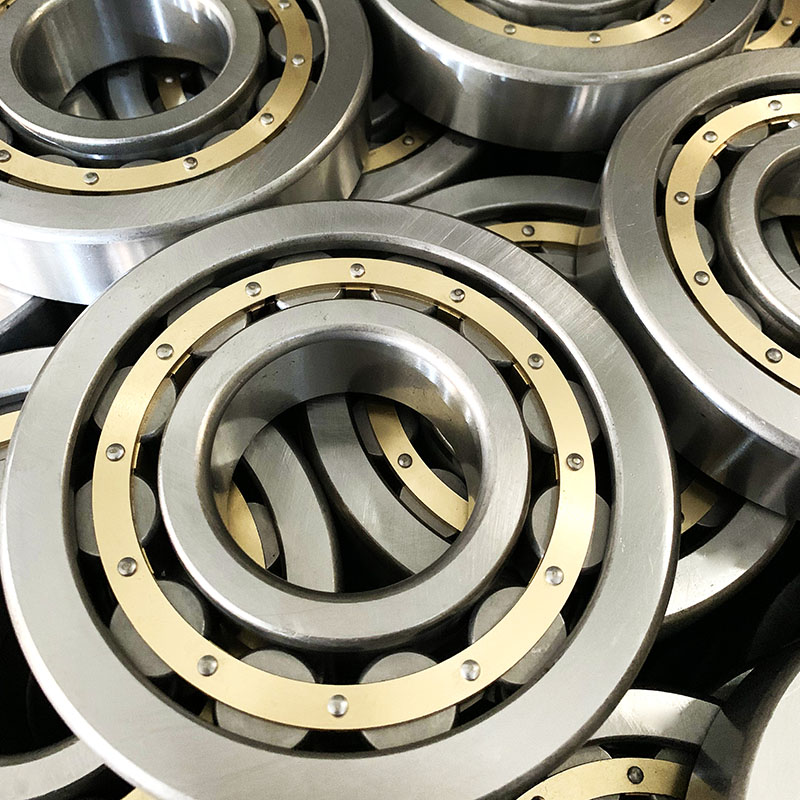

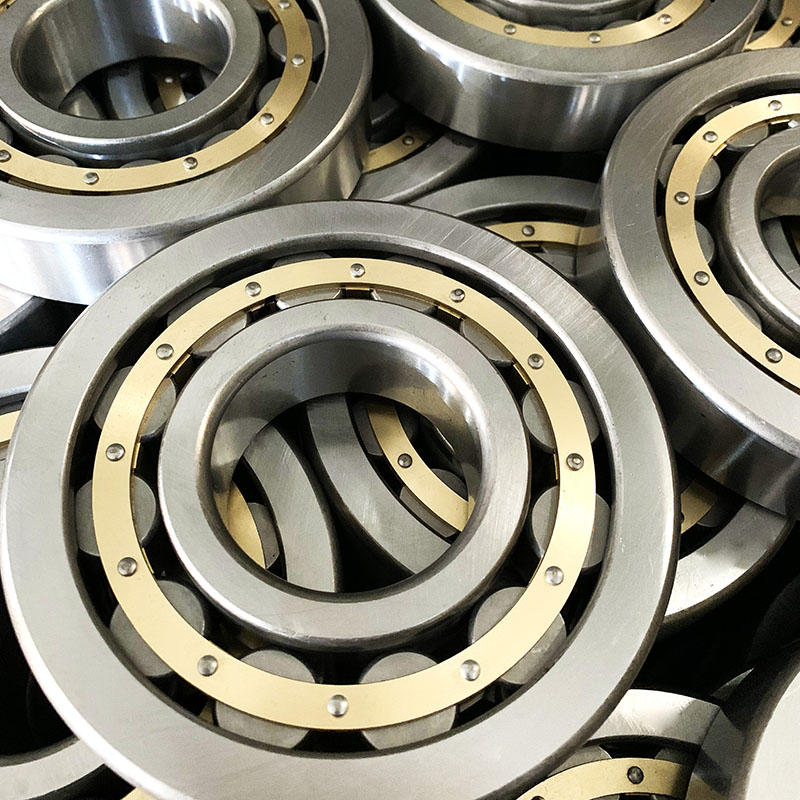

Cylindrical Roller Bearings High Quality

Description

The cylindrical roller and the raceway are linear contact bearings. Large load capacity, mainly bear radial load. The friction between the rolling element and the rim of the ring is small, which is suitable for high-speed rotation. According to the flange of the ring, it can be divided into NU, NJ, NUP, N, NF and other single-row cylindrical roller bearings, and NNU, NN and other double-row cylindrical roller bearings. The bearing is a structure with separable inner ring and outer ring.

Cylindrical roller bearings with inner or outer rings without rims, the inner and outer rings can be axially moved relative to each other, so they can be used as free-end bearings. One side of the inner ring and the outer ring has a double rib, and the other side of the ring has a cylindrical roller bearing with a single rib, which can withstand a certain degree of axial load in one direction. Generally use steel plate stamping cages, or copper alloy carted solid cages. But some also use polyamide forming cages.

Characteristics of cylindrical roller bearings include

● High load-bearing capacity

Cylindrical roller bearings are composed of cylindrical rollers and can withstand greater radial and axial loads than spherical roller bearings.

● High rigidity

Due to the special design of its roller shape, cylindrical roller bearings have high rigidity and stability, and are suitable for high-speed rotation and high load environments.

● Wide scope of application

Cylindrical roller bearings are suitable for various industrial equipment and machinery, such as heavy machinery, metallurgical equipment, mining equipment, lifting machinery, etc.

● Easy installation and maintenance

Compared with other types of bearings, cylindrical roller bearings are relatively simple to install and maintain.

● Good high-temperature performance

When cylindrical roller bearings are made of appropriate materials and lubrication methods, they can provide good high-temperature operating performance.

● Good high-speed performance

Properly designed and processed cylindrical roller bearings can provide better high-speed operation performance.

Cylindrical roller bearings are widely used in industrial fields due to their above-mentioned characteristics.

Product Drawing

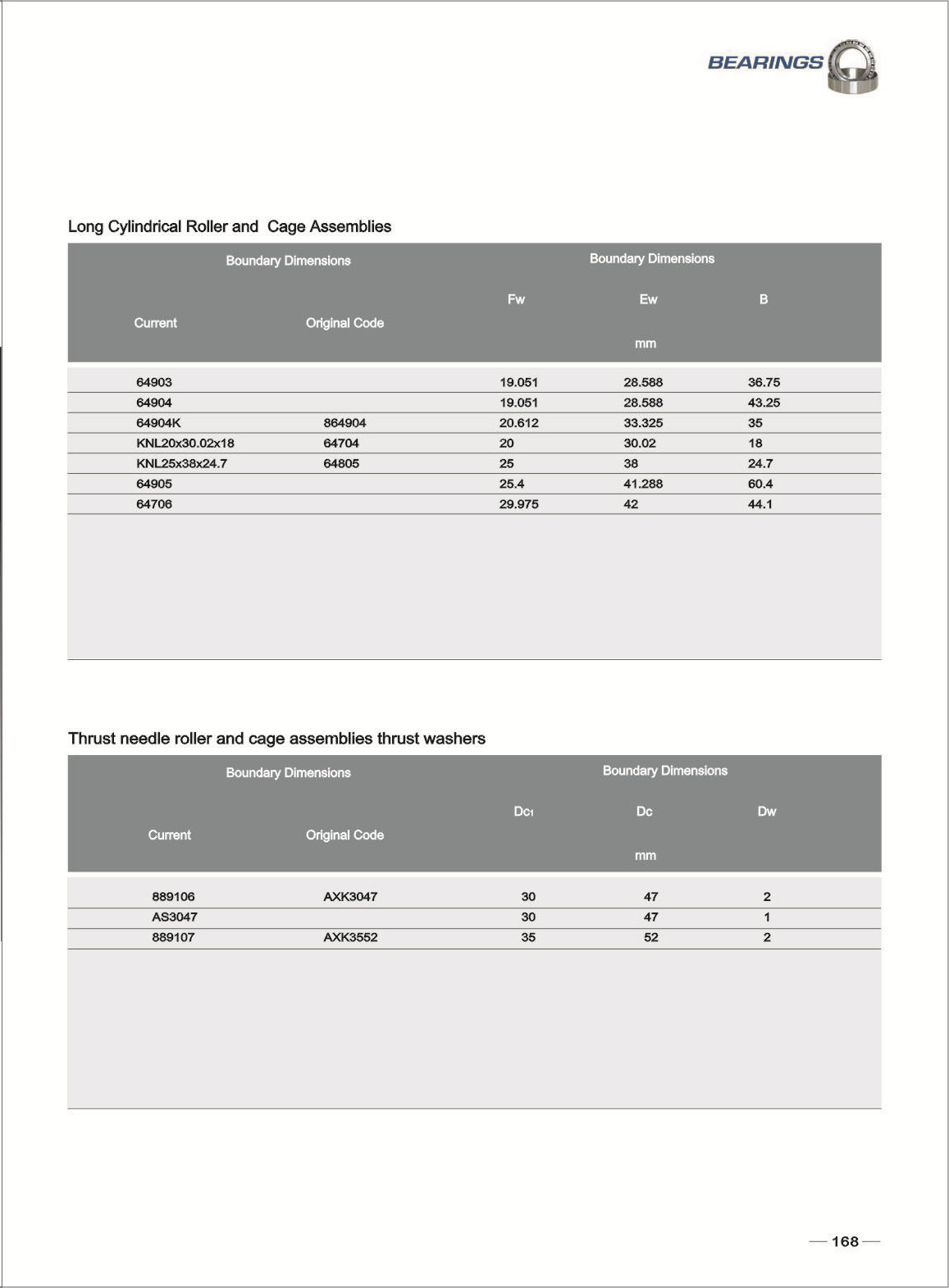

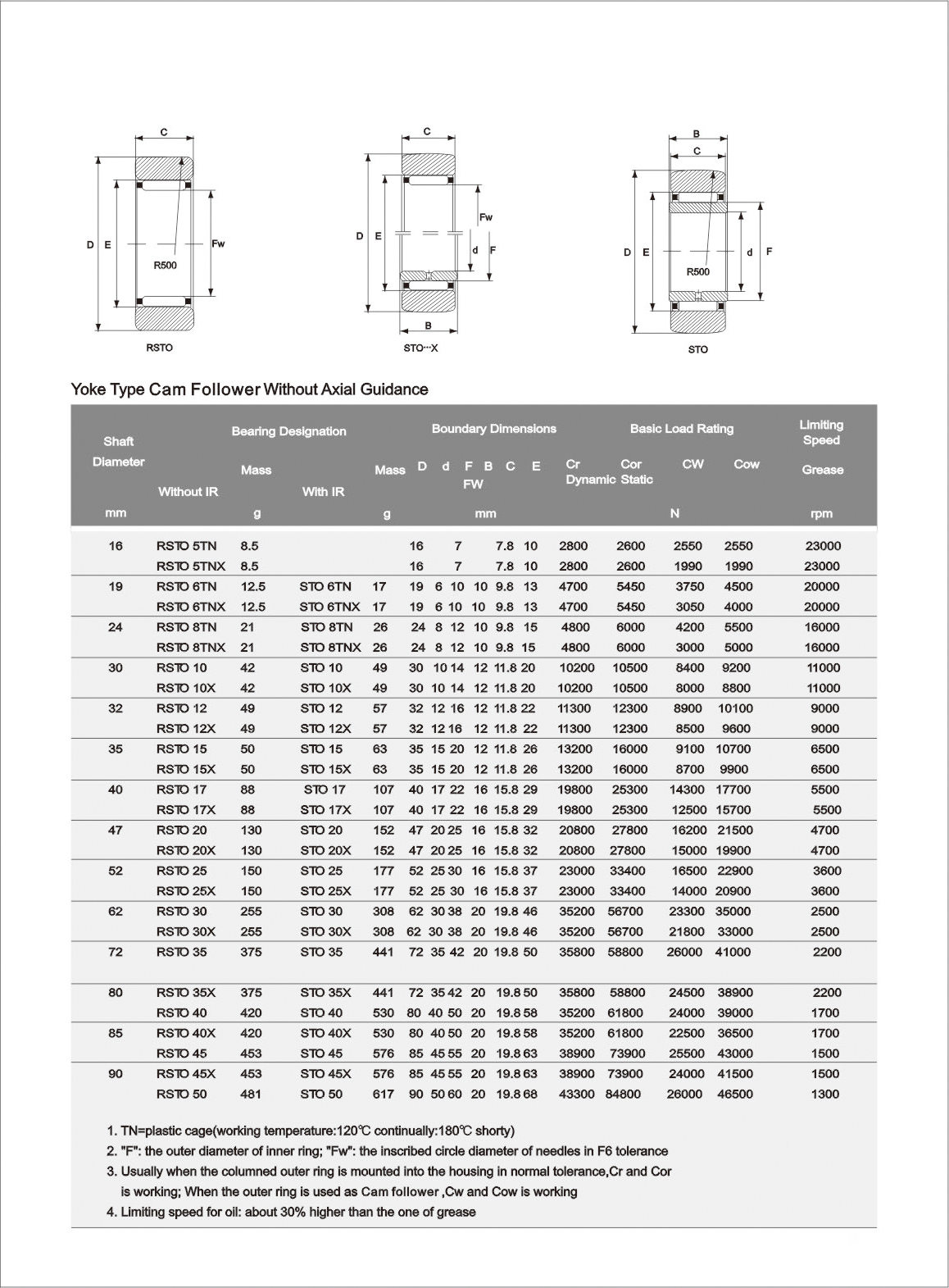

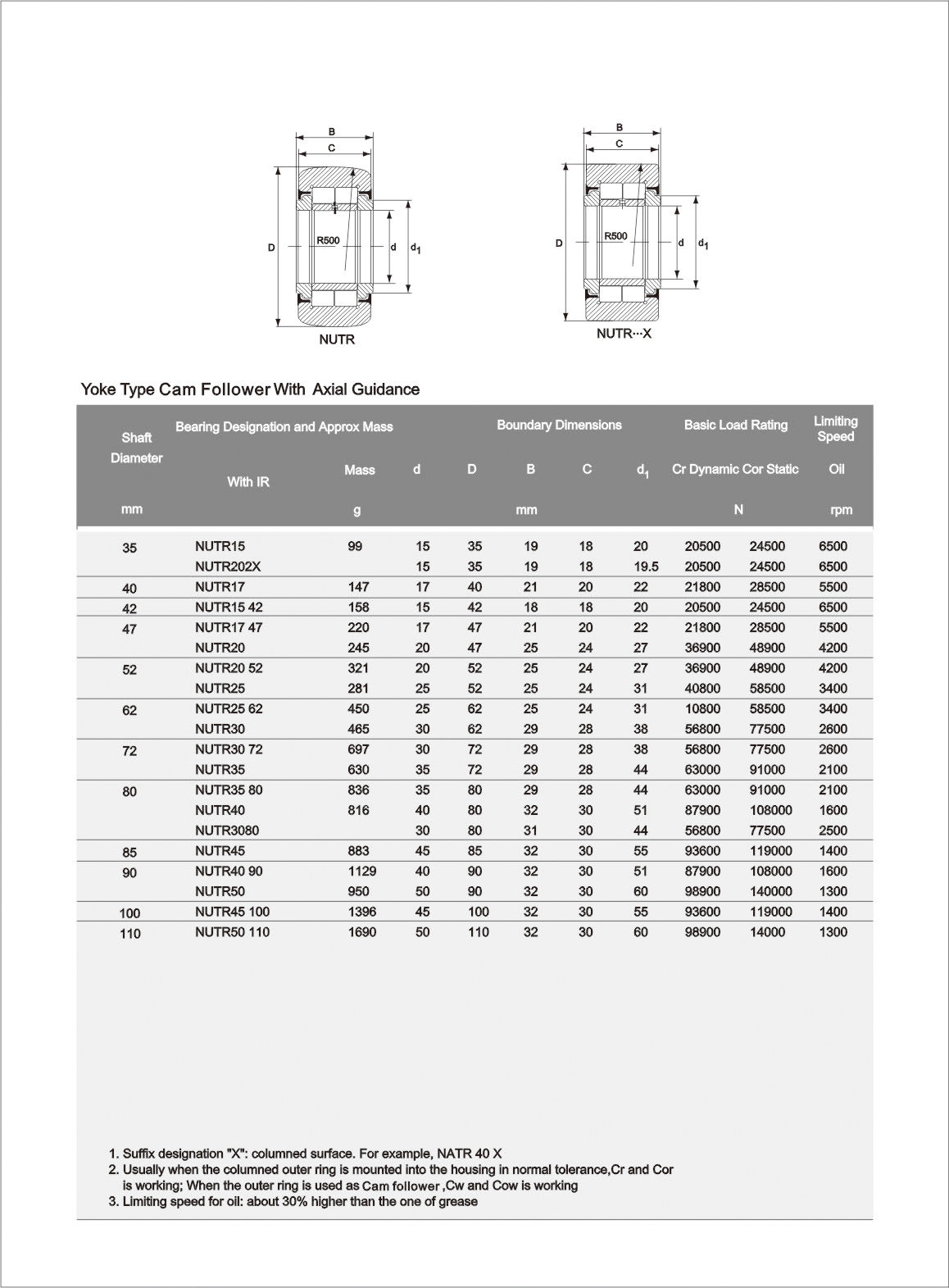

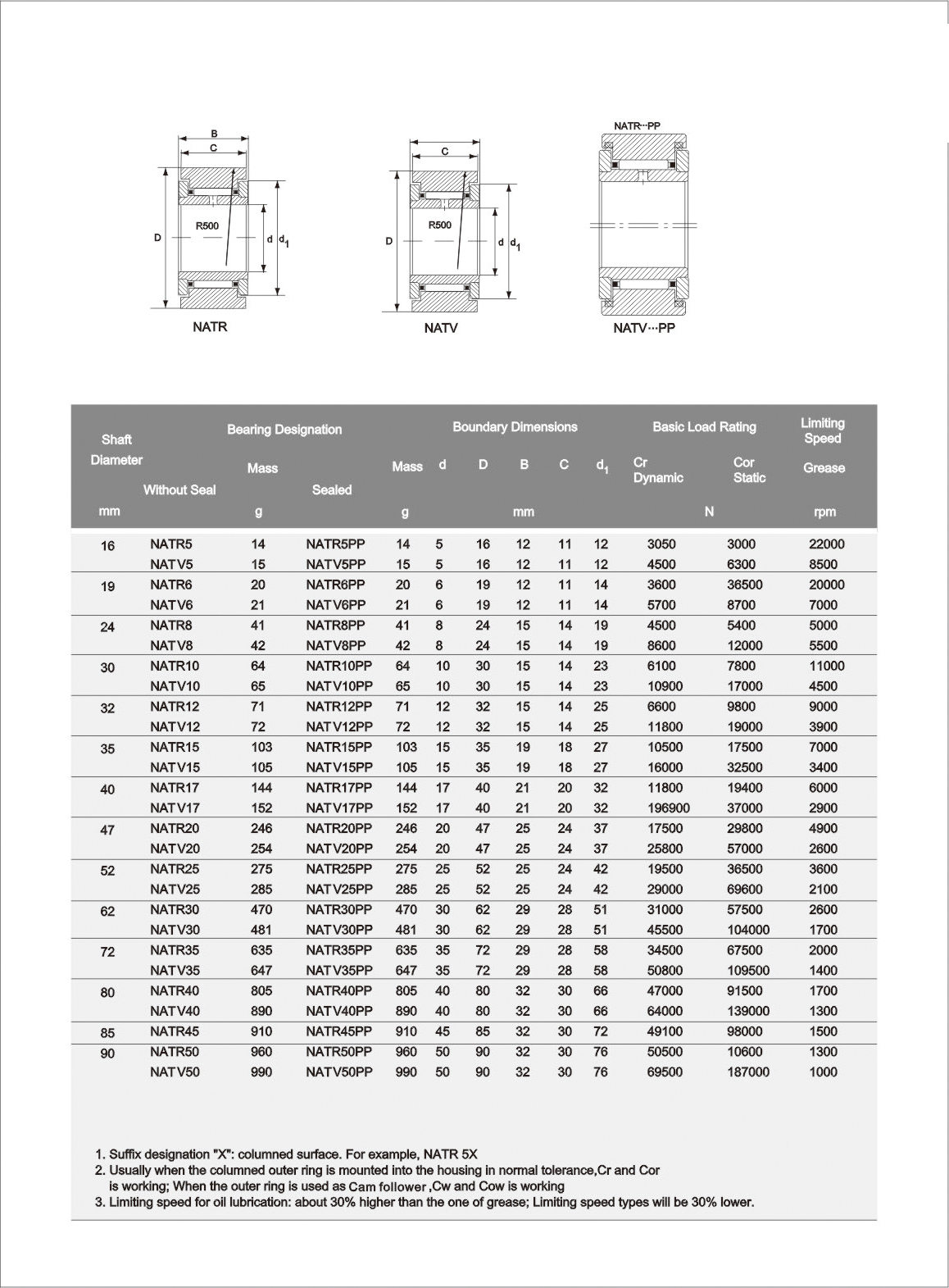

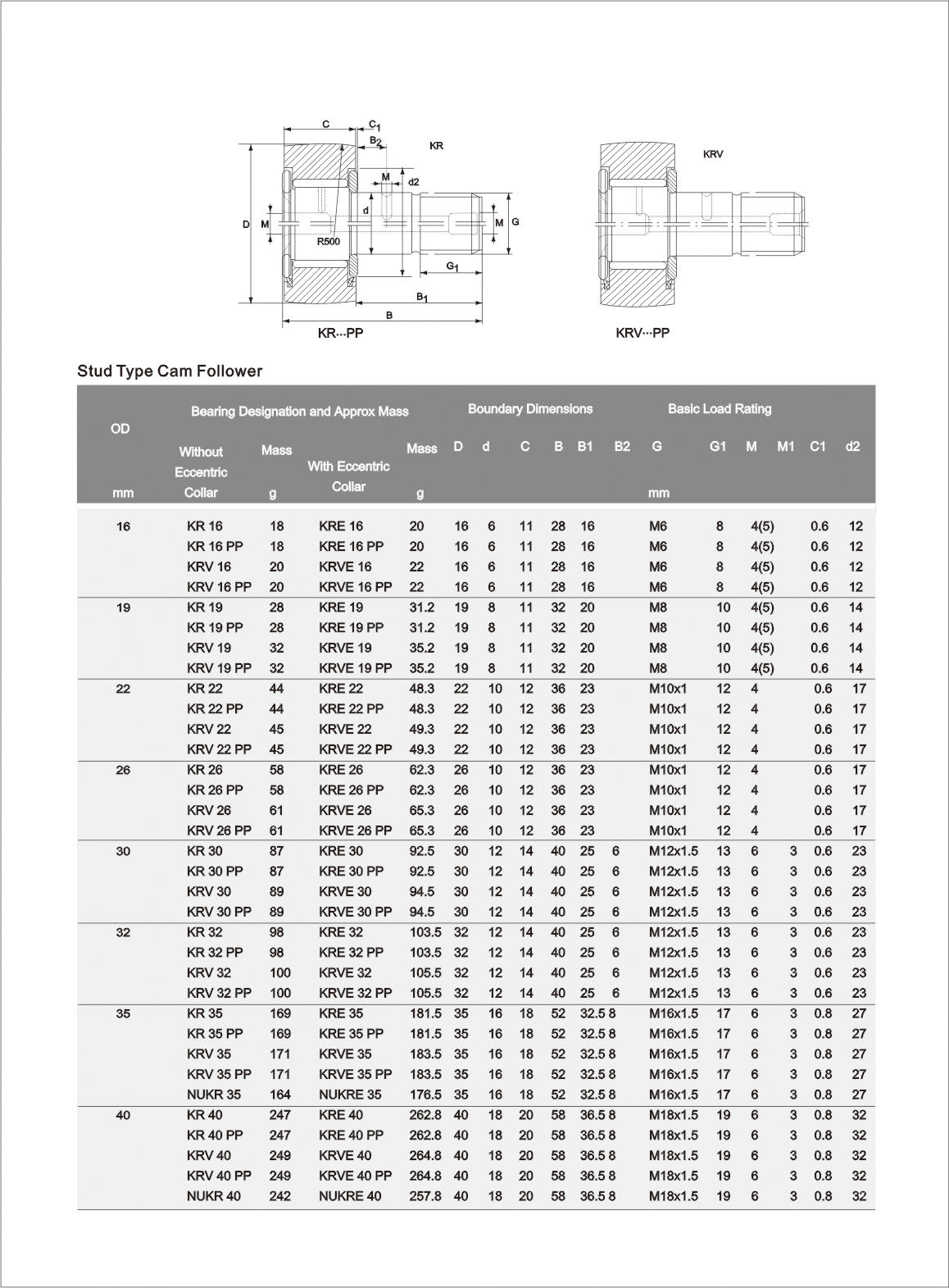

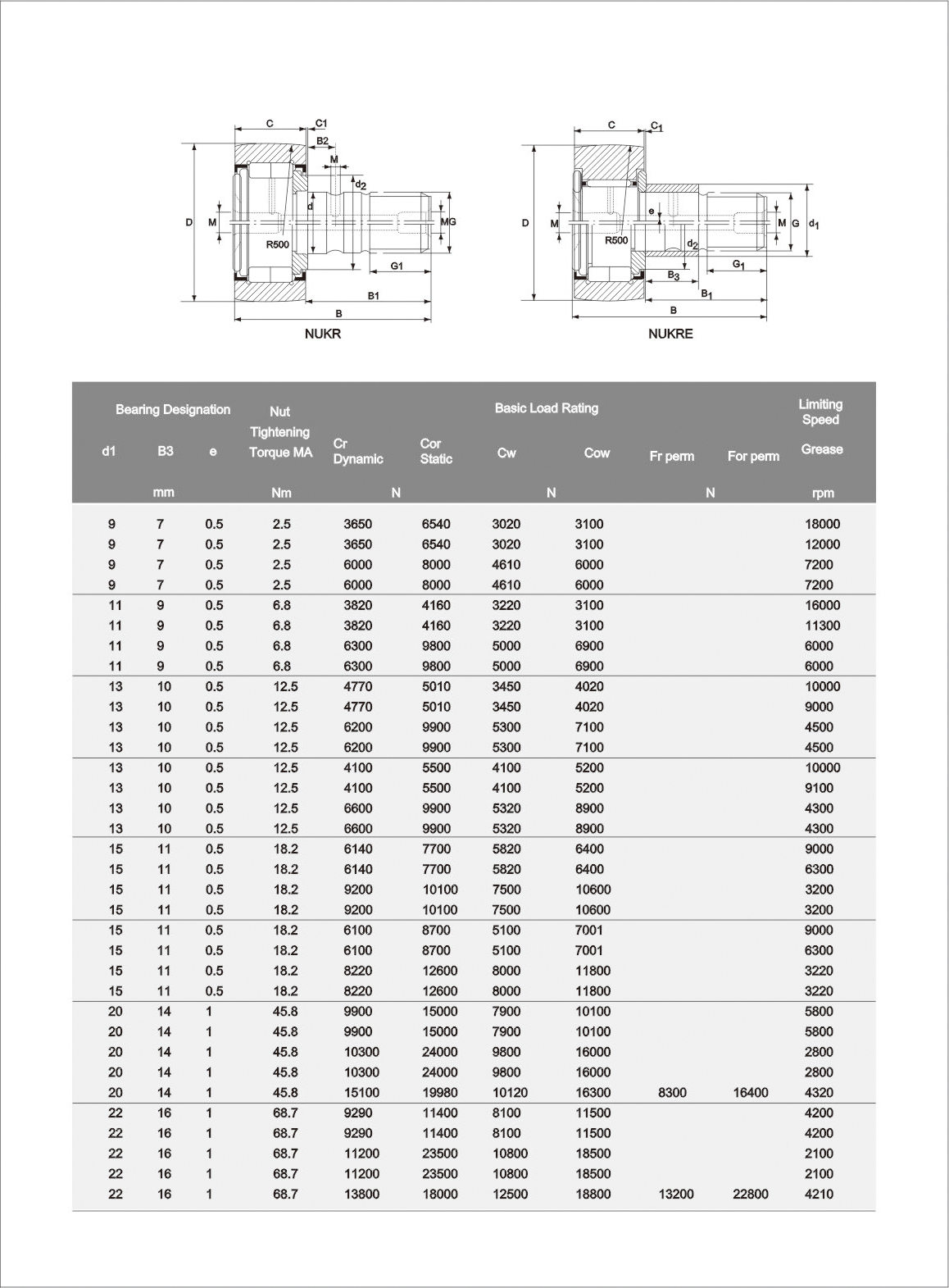

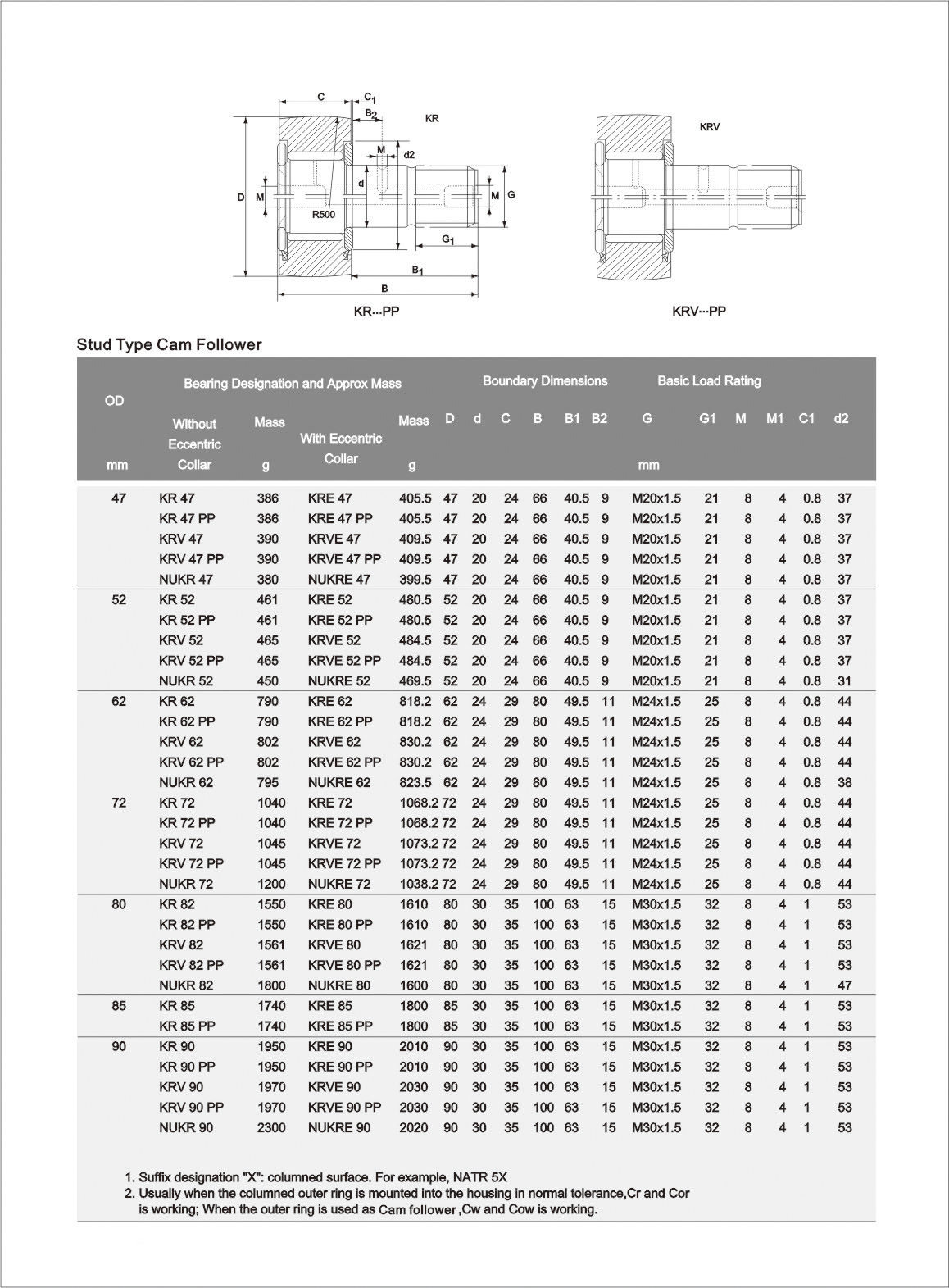

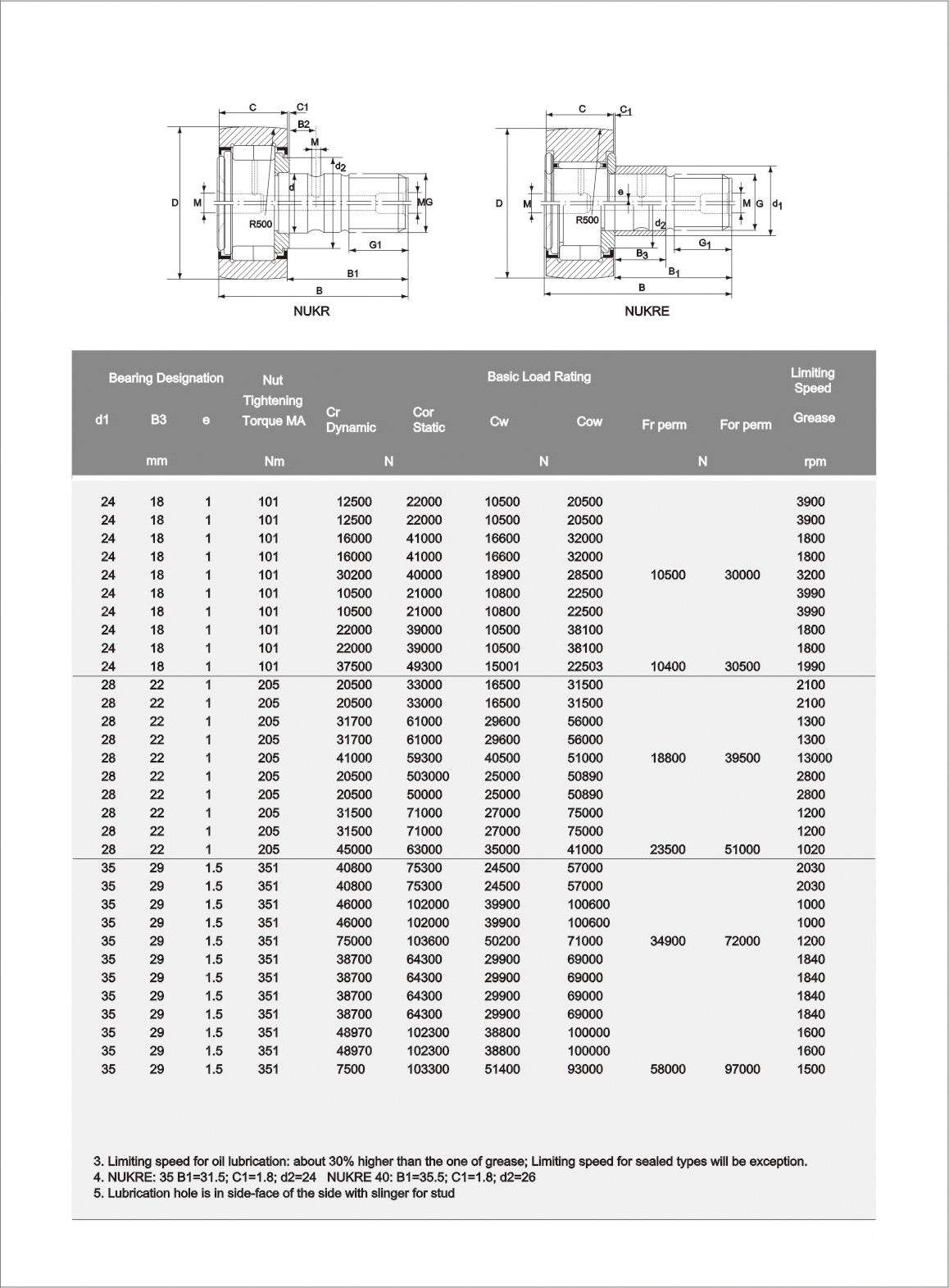

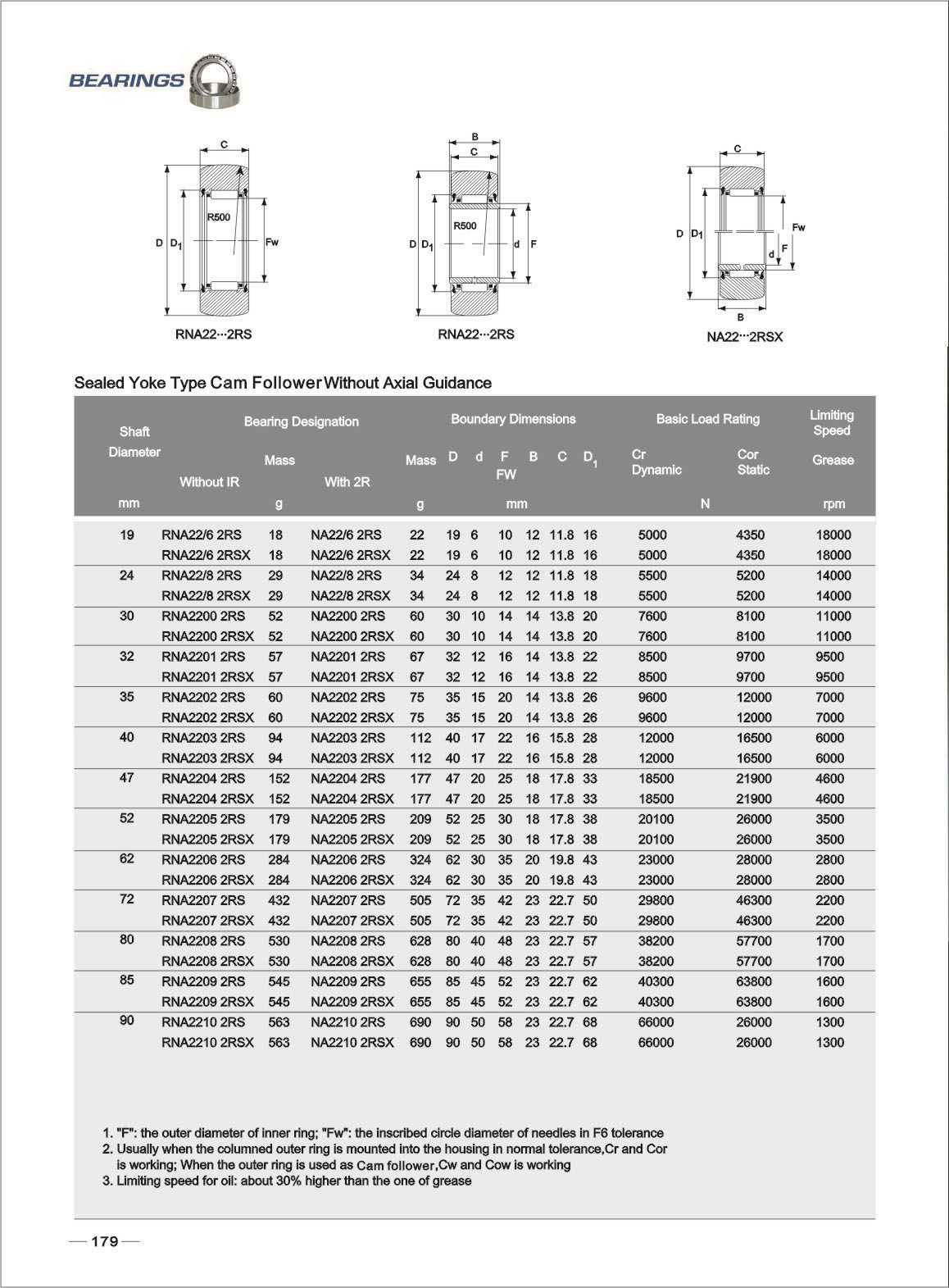

Catalog