Introducing the Ultimate Guide to Bearings: Choosing the Right Type for Your Machine

When it comes to machinery and mechanical rotating parts, one of the most critical components to consider is the type of bearings used.Bearings play a vital role in ensuring smooth and efficient operation, and the correct selection can have a significant impact on the performance and service life of your equipment.In this comprehensive guide, we'll explore the different types of bearings, including plain bearings, spherical bearings, and rolling bearings, and provide valuable insights to help you make an informed decision for your specific application.

Plain bearings are designed without inner and outer rings and rolling elements. They are made of wear-resistant materials and are typically used in low-speed, light-load applications where lubrication and maintenance are challenging.Their simple yet effective design makes them ideal for machinery requiring minimal maintenance and long-term reliable performance.

Spherical bearings, on the other hand, have a spherical contact surface and are ideal for rocking, tilting, and rotational movements.Its unique design allows flexibility and adaptability in a variety of applications, making it a popular choice for machinery experiencing dynamic motion.

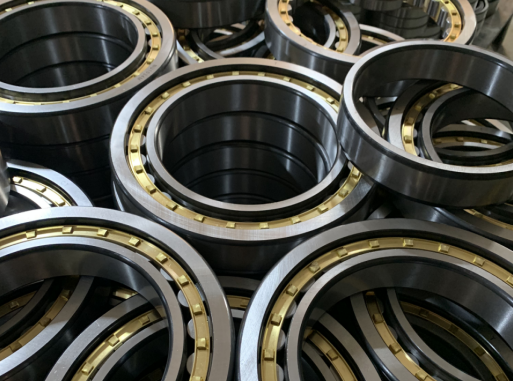

Finally, there are many variations of rolling bearings, including radial bearings, thrust bearings, ball bearings, and roller bearings. Rolling bearings are available in different load capacities and contact angles, offering versatility and precision to meet different operating requirements.

In addition to these main categories, bearings can also be classified according to their structural shape, the number of rows of rolling elements, whether their parts are separable, etc.This wide range of choices ensures you the flexibility to choose the perfect bearing for your specific needs.

But with so many options, how do you determine the right bearing type for your machine? The key is to understand the unique requirements of your application and select bearings that provide the ideal balance between load capacity, speed, accuracy and durability.

For low-speed and light-load applications, such as conveyor systems or agricultural machinery, plain bearings may be the best choice due to their low maintenance requirements and reliable performance. Their simple design and wear-resistant materials make them ideal for long-term use without the need for frequent lubrication or replacement.

If your machinery involves swinging or tilting motion (such as a crane or robotic arm), spherical bearings provide the flexibility and adaptability needed to accommodate these dynamic movements. Its spherical contact surface enables smooth, efficient operation even in challenging environments.

On the other hand, for high-speed and precision-critical applications, such as automotive or aerospace engineering, rolling bearings offer superior performance and reliability. Available in a variety of rolling element types, load capacities and contact angles, you can choose a bearing that meets the exact requirements of your machinery.

In the world of rolling bearings, there are ball bearings and roller bearings, each with its own advantages and applications. Ball bearings are suitable for high-speed operation and light to medium loads, while roller bearings are more suitable for heavy-duty applications and can easily handle radial, thrust and combined loads.

Additionally, for some applications, alignment capabilities during operation are an important consideration.Self-aligning bearings are designed with spherical raceways that can accommodate angular misalignment and movement, making them ideal for machinery that experiences misalignment during operation.Non-aligning bearings, on the other hand, are rigid and resist angular misalignment, providing stability and precision in critical applications.

In summary, choosing the right type of bearing for your machinery requires careful evaluation of your specific requirements, including load capacity, speed, accuracy and environmental conditions.By understanding the unique advantages and applications of plain bearings, spherical bearings and rolling bearings, you can make informed decisions to ensure optimal performance and service life of your equipment.

In summary, selecting the appropriate bearing type is a key factor affecting mechanical performance and reliability. By considering the unique advantages and applications of plain bearings, spherical bearings, and rolling bearings, and understanding their various classifications and structural variations, you can confidently choose the perfect bearing for your specific needs. With the right bearings, you can ensure smooth and efficient operation, reduce maintenance requirements and extend equipment life, ultimately increasing your business's productivity and cost savings.