Bearing Material Types

Bearing material type plays a vital role in bearing performance and life. Material selection affects factors such as load-carrying capacity, friction, wear resistance and corrosion resistance. There are a variety of bearing material types available, each with its own unique properties and applications. In this article, we will explore the different bearing material types, their properties, and the applications for which they are best suited.

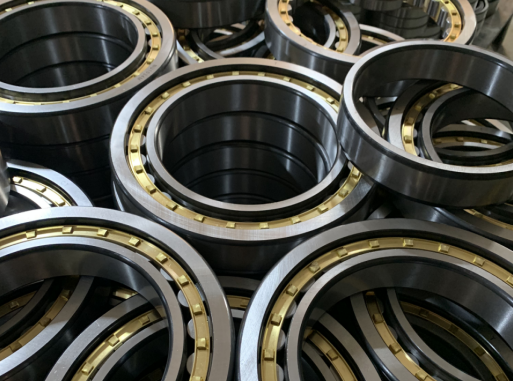

1. Metal bearings

Metal bearings, also called plain bearings, are one of the most common bearing types. They are usually made from materials such as bronze, brass, and steel. Bronze bearings, for example, are known for their excellent wear resistance and ability to withstand heavy loads. Brass bearings have good corrosion resistance and are suitable for applications where the bearings may be exposed to moisture or chemicals. Steel bearings are known for their high strength and durability, making them ideal for heavy-duty applications.

2.Plastic bearings

Plastic bearings are becoming increasingly popular due to their lightweight, corrosion-resistant and self-lubricating properties. They are typically made from materials such as polytetrafluoroethylene (PTFE), nylon, and acetal. PTFE bearings are known for their low friction and excellent chemical resistance, making them suitable for applications where traditional metal bearings may fail. Nylon bearings have good wear resistance and are often used in light load applications. Acetal bearings are highly resistant to moisture and chemicals, making them suitable for use in harsh environments.

3. Ceramic bearings

Ceramic bearings are known for their high hardness, wear resistance, and corrosion resistance. They are typically made from materials such as silicon nitride and zirconium oxide. Silicon nitride bearings have excellent hardness and thermal shock resistance, making them ideal for high-speed and high-temperature applications. Zirconia bearings are known for their high strength and thermal insulation properties, making them suitable for applications where traditional metal bearings may fail.

4. Composite bearings

Composite bearings are made from a variety of materials, usually a metal or plastic matrix reinforced with fibers such as graphite, carbon or aramid. These bearings offer a unique combination of properties such as high strength, low friction and excellent wear resistance. Composite bearings are often used in applications where traditional metal or plastic bearings may fail, such as high loads or high temperature environments.

5. Ceramic hybrid bearings

Ceramic hybrid bearings combine the high strength and durability of steel with the wear resistance and low friction of ceramic. These bearings usually consist of ceramic balls and steel races. They provide superior performance in high speeds, high temperatures and corrosive environments. Ceramic hybrid bearings are commonly used in applications such as electric motors, automotive transmissions and industrial machinery.

In summary, bearing material type plays a vital role in bearing performance and reliability. Material selection should be based on load capacity, friction, wear resistance, corrosion resistance and other factors. There are a variety of bearing materials available, so it is important to choose the right material for each specific application to ensure optimal performance and service life. Whether metal bearings, plastic bearings, ceramic bearings, composite bearings or ceramic hybrid bearings, each material type offers unique properties and advantages for different applications. By understanding the characteristics of each bearing material type, engineers and designers can make informed decisions about the best material for their specific application requirements.